Parylene Thickness - Industry Benchmarks, Cost, Effect on Properties

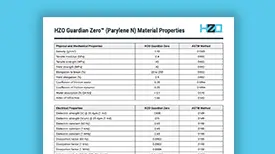

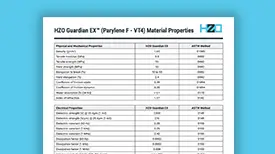

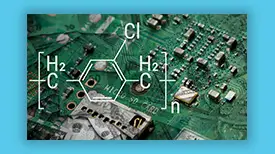

In the world of protective coatings, Parylene is a standout. Its unique, beneficial properties make it a great choice. Many Parylene types have distinct properties, like Parylene C, N, and F (VT-4 or AF-4, for example). By choosing a type, you can tailor Parylene to specific performance requirements.

How Does Parylene Thickness Affect Coating Properties?

The type of parylene dictates coating properties, while the thickness of the Parylene conformal coating determines its protection level. This includes electrical insulation, mechanical protection, and chemical resistance.

Electrical Insulation - A thicker coating usually has a higher dielectric strength. It can withstand greater electrical stress and prevent current leakage.

Mechanical Protection - Thicker coatings shield the substrate from damage, like abrasion better. They also resist mechanical stress.

Chemical Resistance - A thicker layer can delay the penetration of aggressive substances. It can also protect the substrate from corrosive environments for longer.

How Thick Does Parylene Need to Be?

How much Parylene do you need for your application? The answer depends on your design, choice of Parylene, and what environment you need protection from.What is the Best Parylene Thickness for My Industry? - Some Examples

How Thick Should Parylene Be in Different Environments?

Different environments demand specific barrier protection capabilities and, thus, different coating thicknesses. Analyze the threats in your application environment and the coating specs you must meet. Then, you can pinpoint the Parylene thickness you need. Here are some examples:

Moisture and Humidity - A Parylene coating as thin as2 microns can offer surface protection from moisture.

Submersion Protection: A Parylene coating from 5 microns and above will be able to protect most productions from freshwater submersion

Temperature and Humidity: Products that will experience a range of temperature and humidity changes over the lifetime of the product are typically coated at a thickness greater than 15 microns

Chemical and Solvent Resistance: Chemical exposure typically necessitates coatings over 10 microns to prevent permeation and ensure the integrity of the covered components.

Physical Abrasion: Parylene is a soft polymer and while it will not wipe off, it is not suitable to an environment where there will be continual abrasion of the coating.

By analyzing the environmental threats in your application environment and the coating specifications you must meet, you can pinpoint the Parylene thickness you need.

How Do You Measure Parylene Thickness?

Coating thickness can be measured with various techniques. The industry standard method that HZO employes is to use spectral reflectance. This is done for every run in every one of our facilities. Additional methods such as contact Profilometry and Ellipsometry can also be used.

Spectral Reflectance

Spectral reflectance is used for measuring coating thickness by examining the interaction between light and matter at various wavelengths. Spectral reflectance measures how much light reflects from a thin coating over a range of wavelengths and is a non-destructive, non-contact method. Spectral reflectance is commonly used for coatings that range from around 1 to 50+ microns, most often on glass slide witness coupons and sometimes directly on a coated product with sufficiently flat and reflective surfaces.

Contact Profilometry

Contact Profilometry

With contact profilometry, a physical probe moves across the coating surface, registering variations in height to reveal thickness disparities. This mechanical method is respected for its accuracy and ability to produce detailed surface topography maps. However, the very contact nature of this technique might induce damage or introduce deformations to Parylene films, presenting a significant limitation so this Is not used on a a daily basis.

Ellipsometry

Ellipsometry, a non-destructive optical method, analyzes polarized light reflected from the coating surface. The ellipsometry tool infers film thickness by interpreting changes in the light's polarization state. Light interaction with the substrate complicates this analysis, often requiring the tool to perform complex calculations and it needs meticulous calibration to ensure accurate results, especially with non-uniform surfaces. Ellipsometry is more often used for sub-micron thickness coatings, especially on silicon wafer witness coupons.

At HZO, quality is top of mind. Since our inception, we've coated millions of components and haven't had one product return due to coating issues. Watch this video to learn more about our coating process.

Choose HZO as your Parylene Coating Partner

Are you wondering how thick the coating should be on your next project? No problem. Book a DFM consultation and speak to an engineer. They will tell you the next steps.

What is Parylene? Industry Use Cases, Types, Properties

An Overview of Our Parylene Coating Equipment

How Much Does Parylene Coating Cost? - All Things Considered

Mallory is a veteran writer with over a decade of writing experience and has spent over five years at HZO learning about coating technology from the best minds in the industry. Professionally, Mallory is especially interested in the process of problem-solving and watching how the engineering team develops solutions that ensure business requirements are met. Over her years at HZO, Mallory's writing has been cited in industry whitepapers, including "Parabolic Model for Optimum Dry Film Thickness (DFT) of Corrosion Protective Coatings" and "Universal Approach to Integrating Reduced Graphene Oxide into Polymer Electronics." All of Mallory’s blogs are reviewed for accuracy before publication.

Additional Resources

Learn About Parylene Properties With Our Resource Page

Learn How To Incorporate Conformal Coating Into Your Manufacturing Process

Learn About the Thin Film Coating Properties and Processes In Our Webinar

Learn How to Bring Parylene Deposition In-House