Parylene Masking - General Concepts Explained

Conformal coatings are an excellent way to increase the reliability of electronic components in harsh environments. However, this protection can be too much of a good thing without processes to ensure certain areas remain coating-free.

These polymeric films can inhibit the critical functions of specific functions, but the masking process resolves this issue. With proper masking, you can benefit from conformal coating protection without losing functionality.

What is Masking?

Masking is applying a temporary film, boot, tape, or plug to designated assembly components to prevent them from being coated. While masking is important for conventional coatings such as acrylics, epoxies, urethanes, and silicones, Parylene has unique qualities that create a critical need to ensure it is done right.

Quick Introduction to Parylene Masking Techniques

For general guidance on conformal coating masking, the IPC-HDBK-830A handbook provides a good reference. However, because the coating process causes Parylene molecules to penetrate any surface area accessible to air, operators must ensure that all coating keep-out areas resist Parylene coating application, which requires domain expertise.

HZO uses proprietary masking equipment, and our engineers build and customize techniques for every project. However, a short description of general methods follows below.

Parylene masking techniques typically involve precisely sizing materials such as tapes, form-in-place gaskets, and boots to designated masked regions. After applying materials to the appropriate areas, a masking operator will allow peelable masking materials to dry before starting the CVD process, coating the entire component. After coating, the masking material is carefully removed.

Why Proper Masking for Parylene Coating is So Critical

Parylene’s exceptionally high dielectric strength requires you to mask the right areas diligently. A PCBA coated with Parylene would benefit from electrical insulation protection. However, if the connectors on that same PCBA get covered, you won’t be able to plug it in or make connections.

Another reason you must get your Parylene masking process correct is the film's incredible conformality. Where Parylene is allowed to penetrate, pins and moving parts will be completely encapsulated. Although this cohesive and thorough presence of coating is typically considered a benefit, additional cost and labor to remove the Parylene from the keep-out areas will be required with incorrect masking implementation. In other words, it’s best to prevent instead of rework, which can be challenging due to Parylene’s strong chemical resistance properties.

Why It Can Also Be More Complicated

When you mask for Parylene application, the stakes are higher. Once it’s on, removing the coating will be a struggle without a knowledgeable partner with tools and techniques to make rework easier. The fact that masking for Parylene is also more complex, requiring more skill, raises further complications.

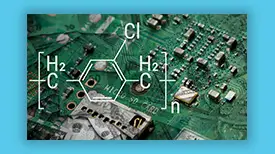

Without skill and experience, masking for Parylene is more challenging than general conformal coating masking due to the chemical vapor deposition process (CVD) used to apply the coating.

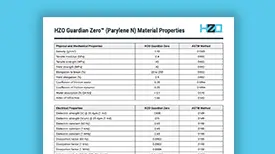

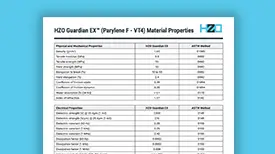

Learn about Parylene Thickness

Unlike conventional conformal coatings applied as liquids, Parylene is applied as a vapor, which means you are masking against a gas. Therefore, a much better barrier is required with the Parylene masking process, as vapor can more easily bypass masking materials.

Other masking considerations include:

- The need to validate if all components are hermetically sealed or not due to the vacuum nature of the CVD process

- Chamber maintenance

- Masking more than just keep-out locations may be required

- The need for specific fixturing

- Materials need to be thoroughly cured before coating, and outgassing should be avoided

The list below includes components that, in many cases, should not be coated:

- MEMs

- Actuators

- Mating connectors and pins

- Test points needed before assembly

- Ground contacts

Parylene Coating With HZO

If you are masking for Parylene, you must implement the process correctly. Further, Parylene masking requires considerable expertise and experience to identify factors affecting masking success. These might include Parylene masking materials, the Parylene type, and the different areas that must be coated. Proper timing is also essential, as there is a relationship between the masking and coating processes. Any timing issues can impede coating quality. Managing electrostatic discharge is also a concern when masking.

Fortunately, our engineers have years of this experience, creating custom masking plans for customers with electronic products of all sizes, shapes, and functions. We have also developed industry-leading masking equipment that can automate and semi-automate the process for larger productions.

Reach out today if you would like a consultation to discuss why to use Parylene, our scalable Parylene coating equipment, or our automated masking processes that decrease Parylene coating costs.

Parylene Coating Removal - Methods & Best Practices for Each

An Overview of Our Parylene Coating Equipment

What is Parylene? Industry Use Cases, Types, Properties

Mallory is a veteran writer with over a decade of writing experience and has spent over five years at HZO learning about coating technology from the best minds in the industry. Professionally, Mallory is especially interested in the process of problem-solving and watching how the engineering team develops solutions that ensure business requirements are met. Over her years at HZO, Mallory's writing has been cited in industry whitepapers, including "Parabolic Model for Optimum Dry Film Thickness (DFT) of Corrosion Protective Coatings" and "Universal Approach to Integrating Reduced Graphene Oxide into Polymer Electronics." All of Mallory’s blogs are reviewed for accuracy before publication.

Additional Resources

Learn About Parylene Properties With Our Resource Page

Learn How To Incorporate Conformal Coating Into Your Manufacturing Process

Learn About the Thin Film Coating Properties and Processes In Our Webinar

Learn How to Bring Parylene Deposition In-House