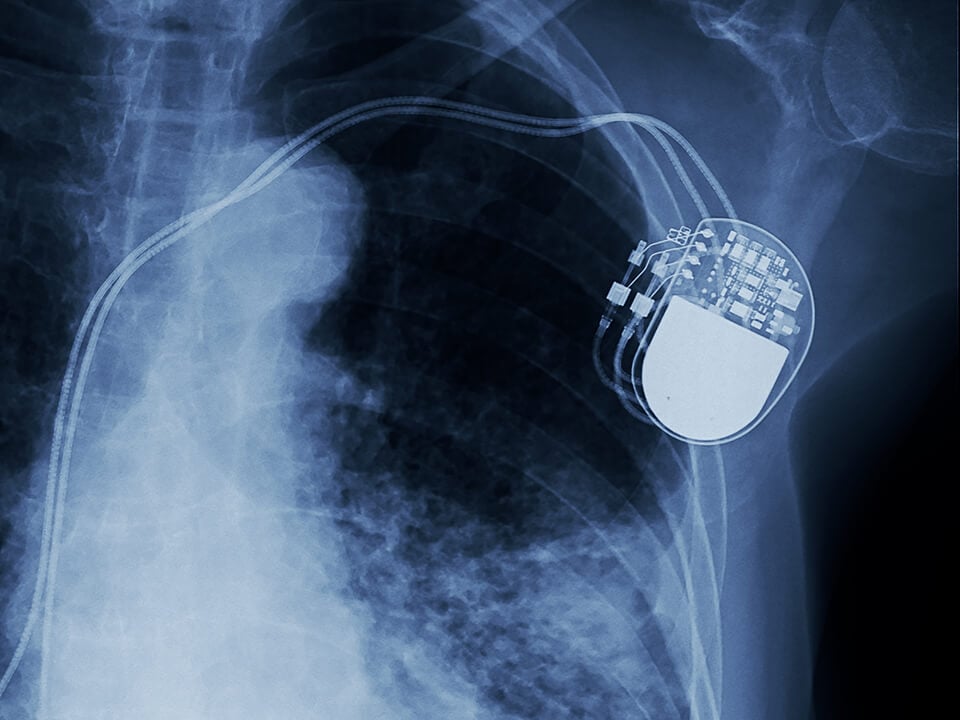

Integrate More Features While Reducing Size With Medical Device Coatings

HZO coatings surpass legacy protection methods for more comfortable and effective connected medical device products.

Reliability, Comfort, and Function

Reliability in Harsh

Environments

Hydrophobic Medical Coatings Tested for 1,000 Hours Continuous Submersion

Conformal Coating Barrier Properties

| Polymer | Gas Permeability at 25 °C, (cc·mm)/ (m2·day·atm) | WVTR (g·mm)/ (m2·day) |

||||||

| N2 | O2 | CO2 | H2 | H2S | SO2 | CI2 | ||

| Parylene C | 0.4 | 2.8 | 3.0 | 43.3 | 5.1 | 4.3 | 0.1 | 0.08 |

| Parylene N | 3.0 | 15.4 | 84.3 | 212.6 | 313 | 745 | 29.2 | 0.59 |

| Parylene D | 1.8 | 12.6 | 5.1 | - | 0.6 | 1.9 | 0.2 | 0.09 |

| Parylene F (VT-4) | - | 16.7 | - | - | - | - | - | 0.28 |

| Epoxy (ER) | 1.6 | 4 | 3.1 | 43.3 | - | - | - | 0.94 |

| Polyurethane (UR) | 31.5 | 78.7 | 1.81 | - | - | - | - | 0.93 |

| Silicone (SR) | - | 19,685 | 118,110 | 17,717 | - | - | - | - |

Parylene Barrier Properties Compared to Conventional Coating

EXCELLENT CHEMICAL RESISTANT TO SOLVENTS

Parylene Resistance to Acids Bases and Corrosives

|

Acids, Bases, Corrosives |

| Hydrochloric acid, 10% |

| Sulfuric acid, 10% |

| Nitric acid, 10% |

| Hydrofluoric acid, 10% |

| Sodium hydroxide solution, 10% |

| Ammonium hydroxide solution, 10% |

| Hydrogen peroxide in water (H202) |

HZO Coating Resistance to Acids, Bases, and Corrosives - Not an Exhaustive List

HZO COATING RESISTANCE TO ORGANIC SOLVENTS

Parylene Resistance to Organic Solvents

|

Organic Solvents Include |

| n-Octane |

| Toluene |

| Chlorobenzene |

| Pyridine |

| 2-Propanol (IPA) |

| Acetone |

HZO Coatings Protect Medical Devices From:

Sweat and Sebum

Cleaning fluids

Dust

Dirt

Condensation

Humidity

Atmospheric Contaminants

ELECTRICAL INSULATION WITHOUT THICKNESS

Parylene Dielectric Strength

| Property | Parylene N | Parylene C |

| Dielectric Strength short time, V/mil (1-mil thick) | 7,000 | 5,600 |

| 60 Hz | 2.65 | 3.15 |

| 1 kHz | 2.65 | 3.1 |

| 1 MHz | 2.65 | 2.95 |

| 60 Hz | 0.0002 | 0.02 |

| 1 kHz | 0.0002 | 0.019 |

| 1 Mhz | 0.0006 | 0.013 |

Improve Comfort for Devices Worn on the Body

Reduce Weight and Bulk of Medical Devices

Mechanical Seal Breach

HZO Coatings

One week after water exposure

Biostable Coatings Ideal for the Human Body

FDA compliant with a USP XII, Class VI biocompatibility rating

Reliable performance at normal body temperature, with a temperature range of -200° C through 80° C

Non-irritating performance, can be worn on the skin

Enhance Function

Optimize Lubricity While Enhancing Reliability

Meet Green Regulations

-

Prop 65, RoHS, REACH Compliant

-

No VOCs

-

No Solvents

-

No Catalysts

-

No Disposal

-

No Pollution Threats

Meet IP Ratings with Minimal Thickness

| Thickness (μm) | 0.1 to 5 | 5 to 12.5 | 12.5 to 25 |

| Relevant Standards | UT Type in IPC-CC-830C | UT Type IPC-CC-830C | IPC-CC-830B |

| Protection Level | IPX3 / IPX4 | IPX4 / IPX7 | IPX7 / IPX8 |

| Appropriate Products | Consumer Electronic & MEMS Devices | Consumer & Industrial Electronics | Aerospace, Automotive, Industrial, Mission-critical Medical Devices, Telecom, & Other High-Reliability Markets |

Facilitate Electrical Communication

-

Low dielectric constant enures minimal energy loss in RF signals

-

Thinness of coatings ensures signal transmission integrity

Transparent Coatings Don’t Impair Optical Signal Quality

Medical Applications

Wearable medical devices

Continuous Glucose Monitors

Hearing Aids

Catheters

Is your project not listed? We may still be able to help.

Processes to Lower Cost

Rework expertise

IP (intellectual portfolio) backed masking automation reduces labor and costs (manual masking also available)

DFM services optimize processes from beginning to end

Scalability and Flexibility

Decrease turnaround time with capital equipment

Throughput can be two times faster than industry standard

Factory-in-factory model or outsource coating to global locations

Expertise and Dedication to Quality

Millions of components coated, no product returns attributed to coating issues

Dedicated engineers with domain experience

Accountable company with turnkey solution

Additional Resources

Learn How to Enhance the Reliability of Your Medical Device Product Design