Sweat, Saltwater, and Liquid Submersion Protection at 50% Thickness of Conventional Coatings

HZO coatings can meet any IP rating with a scalable, cost-efficient, turnkey solution.

Meet Specifications with Superior Coating Properties

Electrical Properties

| ELECTRICAL PROPERTIES | HZO PARYLENE C | ASTM |

|---|---|---|

| Dielectric strength (V) @ 25.4 um (1 mil) | 5,500 | D149 |

| Dielectric strength (V/um) @ 25.4 um (1 mil) | 220 | D149 |

| Dielectric constant (60 Hz) | 3.13 | D150 |

| Dielectric constant (1 kHz) | 3.01 | D150 |

| Dielectric constant (1 MHz) | 2.92 | D150 |

| Dissipation factor (60 Hz) | 0.022 | D150 |

| Dissipation factor (1 kHz) | 0.017 | D150 |

| Dissipation factor (1 MHz) | 0.013 | D150 |

| Volume resistivity (23 C, 50% RH, cm) | 6.0 x 1016 | D257 |

| Surface resistivity (23 C, 50% RH, ) | 1.0 x 1015 | D257 |

Low dielectric constant with good high-frequency properties

Good dielectric strength

High bulk and surface resistance

Insulation

Barrier Properties

| Polymer | Gas Permeability at 25 °C, (cc·mm)/ (m2·day·atm) | WVTR (g·mm)/ (m2·day) |

||||||

| N2 | O2 | CO2 | H2 | H2S | SO2 | CI2 | ||

| Parylene C | 0.4 | 2.8 | 3.0 | 43.3 | 5.1 | 4.3 | 0.1 | 0.08 |

| Parylene N | 3.0 | 15.4 | 84.3 | 212.6 | 313 | 745 | 29.2 | 0.59 |

| Parylene D | 1.8 | 12.6 | 5.1 | - | 0.6 | 1.9 | 0.2 | 0.09 |

| Parylene F (VT-4) | - | 16.7 | - | - | - | - | - | 0.28 |

| Epoxy (ER) | 1.6 | 4 | 3.1 | 43.3 | - | - | - | 0.94 |

| Polyurethane (UR) | 31.5 | 78.7 | 1.81 | - | - | - | - | 0.93 |

| Silicone (SR) | - | 19,685 | 118,110 | 17,717 | - | - | - | - |

Barrier Protection for Resilient Products

Resistant to:

SWEAT

HUMIDITY

SOLVENTS

MOISTURE

Simplify Reliability

Meet Any IPX Claim

-

Splash or submersion is possible with HZO coatings

-

Tested for over 1,000 hours of submersion

Meet Sustainability Market Claims and Regulations

-

HZO Parylene coatings are UL 94-VO certified

-

HZO has non-halogenated RoHS, REACH and Prop 65 compliant coatings

HZO Coatings have:

-

No VOCs

-

No Solvents

-

No Catalysts

-

No Disposal Issues

-

No Pollution Threats

-

No Cure Time

-

Biostable

-

Biocompatible

Reduce eWaste and Promote Reuse and Repair with Long-Lasting Coating Material

Lifetime of HZO Parylene coatings at different temperatures in air (with oxygen).

| 60 °C | 80 °C | 135 °C | 150 °C | |

|---|---|---|---|---|

| Parylene C | ~100 years | ~20 years | ~70 hours | ~24 hours |

| Parylene N | ~10 years | ~1 year | ~9 hours | ~1 hour |

Coating Properties

Uniform & Pinhole-Free

No voids or gaps for ingress.

Optically Transparent

Excellent Conformality

Can completely penetrate voids as narrow as 0.01mm.

No Catalysts

No initiators in polymerization process. Free from trace ionic impurities.

Minimize Coating Thickness

Thin layers facilitate RF signal transmittance

| THICKNESS (μm) | 0.1 TO 5 | 5 TO 12.5 | 12.5 TO 25 |

|---|---|---|---|

| Relevant Standards | UT Type in IPC-CC-830C | UT Type in IPC-CC-830C | IPC-CC-830B |

| Protection Level | IPX3 / IPX4 | IPX4 / IPX7 | IPX7 / IPX8 |

Consumer Electronics Coating Applications

Wearables

Hearables

Smart Home

Have an application that isn't listed?

Read about other markets we serve.

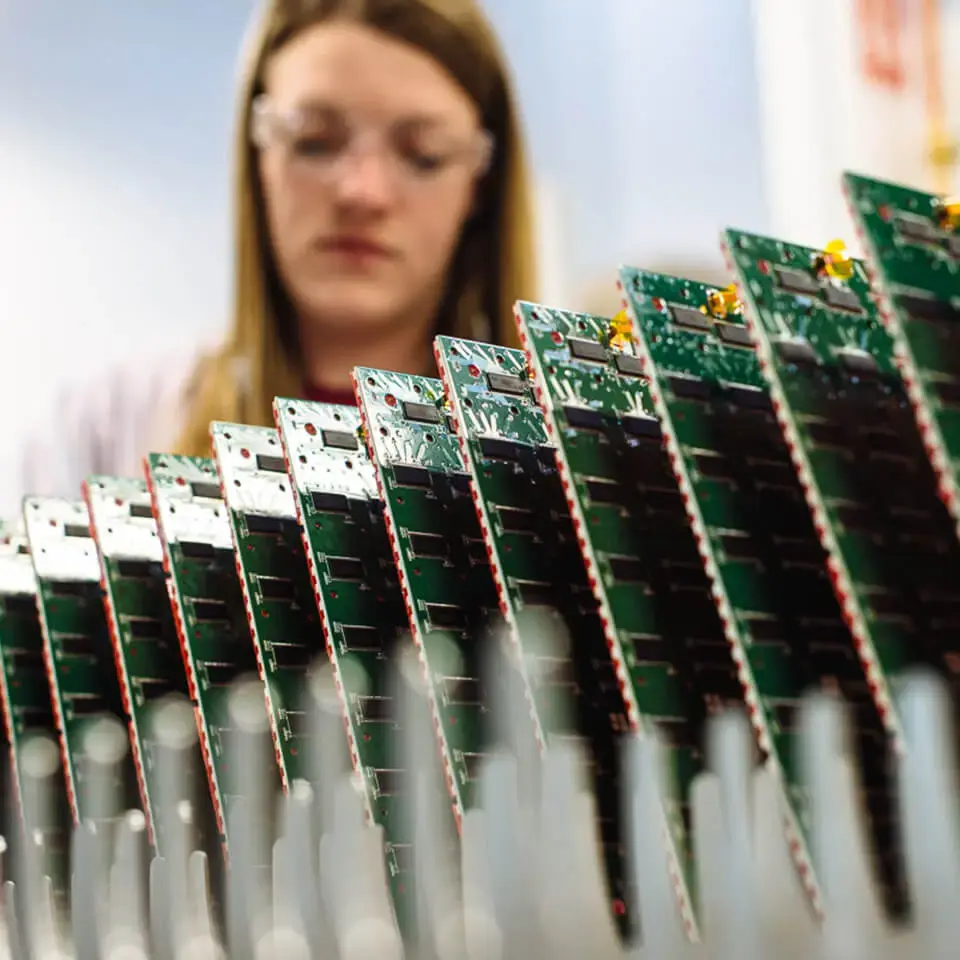

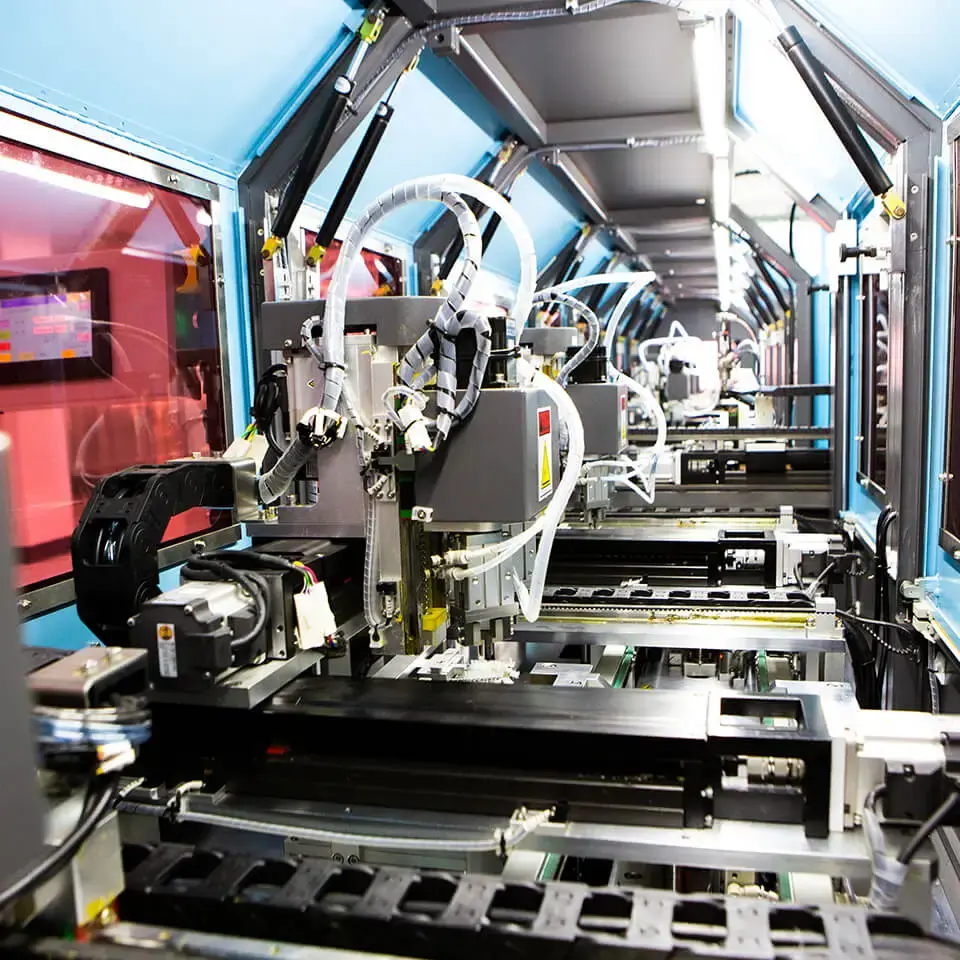

Scalability

Mass-Scale Production

Meet mass-scale production within budget or deadline.

Decreased Turnaround

Decrease turnaround time with our equipment designed in-house.

Single Batch

10,000-20,000 hearable components or batteries coated in single batch.

No Catalysts

No initiators in polymerization process. Free from trace ionic impurities.

Coating Process for High Volume Applications

Validation

-

Beginning with provided samples, HZO engineers determine the best coating solution to meet the customer’s protection and manufacturing requirements.

-

HZO engineers work with the customer to integrate their solution into the product’s manufacturing process.

-

Models include coating as a service or direct integration of HZO’s equipment and processes into the production process.

Pre-Production

-

Pre-processing begins with inspection for quality standards and control for product tracking.

-

When required, masking of areas where protection is not needed can be manual or fully automated.

-

High-speed equipment applies masking materials to pre-determined areas of the product’s substrate.

Production

-

The products to be coated are placed inside large HZO coating chambers with a unique cube-shaped design to optimize component throughput.

-

The chemical vapor deposition process begins as the raw material is sublimated into a vapor phase.

-

After pyrolysis, the vapor flows into the vacuum chamber where it is deposited at a low temperature, forming a uniform, nano to microns-thin coating.

-

Typically coating at two times faster throughput than the industry average, the coated components are removed and placed into post-production.

Post-Production

-

After coating, any masking materials are removed with complex accuracy and dexterity, either manually or automated.

-

Laser scoring, ablation, and automated inspection can help mitigate touchpoints.

-

Each product is optically inspected for quality before being sent out.

-

The components are passed along to the next stage in production.

Cost

- IP (intellectual portfolio) backed masking automation reduces labor and costs

- Automate, Semi-automate, and Manual Masking Available

- Rework expertise

Quality

Millions of components coated, no product returns attributed to coating issues

Market Experience

Fortune 100 consumer electronics customers

Are HZO Protection

Solutions Right for You?

Additional Resources

Learn About HZO's Partnership With a Fortune 100 Consumer Electronics Company

Learn About Why You Need Consumer Electronics Protective Coatings

Learn How to Enhance the Reliability of Your Consumer Electronics Product Design