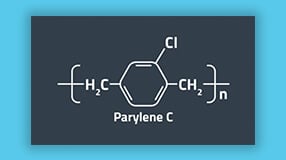

Overcoming Parylene Process Problems

Video Transcript

00:11

So I think the challenges that HZO deals with primarily fall into four different categories. Cost, quality, footprint, and logistics in terms of scaling up. To address cost, as programs scale up and volume maybe starts small, but then will get larger and require more footprint, more space, we are very experienced in being able to transition a program from one location.

00:39

to another location that's more appropriately sized or has capacity, and we can do those transitions seamlessly. As does any process, as you scale up, quality can become at risk. But at HDL, we are very meticulous when it comes to documentation and training, and we have a very regimented kind of step-by-step process as we scale up and increase throughput for any given program. To maintain the high quality and high yield,

01:09

that we might have at lower volumes and attention to detail, we make sure that we appropriately scale up and are able to rely on our documentation and training. Footprint is another concern when it comes to scaling up. One thing that we are able to offer is our large proprietary chambers that we use for coating. They are very efficient in terms of floor space that they require to do high volumes of product.

01:39

So as the volume increases, we often can rely on a single chamber to do that high volume, whereas other coding processes may require several smaller chambers, which ultimately take up additional space on any given production floor. Also regarding footprint, in many cases, the HDL coding process is replacing an existing process, the customer does, for protection. And so...

02:08

Rather than having to use additional floor space, we will often make it so that we can just use that same floor space or reduce the total amount of floor space that they require because they're removing an existing process. Another challenge is logistics. Logistics, we address that by having a variety of different locations that we can offer to our customers to be close to where the parts are manufactured.

02:37

the ability to work with the applications engineering team and find a way where we appropriately fit into the manufacturing stage and the manufacturing process where we can minimize the risk of logistics by being able to potentially coat smaller parts or parts that are in a certain part of the stage of the manufacturing process where they're easier to ship if we are needing to ship to certain locations globally. We also offer

03:03

in-house options where we can provide our equipment right on your production floor so there is no logistics required as we scale up. So those are just some of the few ways that we address the most primary challenges as we scale up the paraling process.

Are HZO Protection

Solutions Right for You?

Additional Resources

Learn About HZO's Partnership With a Fortune 100 Consumer Electronics Company