Parylene Coating Services

Product design often struggles to balance many goals that can seem conflicting. You must reduce time to market, stay on budget, and keep electronics lightweight. You must also ruggedize your products for harsh conditions. Conformal coatings, especially Parylene films, can help you meet these goals.

What are the Benefits of Parylene?

Cost Reduction

Reduce corrosion-related costs associated with repairs, refunds, and service calls.

Cut down on product recalls and enhance product reliability.

Lower total cost of ownership with long-lasting, durable protection.

Functionality

Meet specifications for dielectric, thermal, and chemical resistance properties.

Help lighten products, improving fuel and energy efficiency, and mechanical stability.

Used as an anti-reflective (AR) coating for sensors

Excellent biocompatibility and biostability

Helps products meet ASTM, FDA, IPC, ISO, JEDEC, MIL, UL, and other industry standards

Risk Mitigation

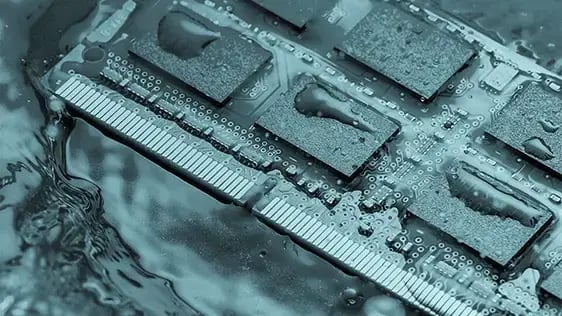

Reduce the risk of corrosion from humid, salty, and sulfurous environments.

Reduce the risk of damage due to solvents and water exposure.

Reduce the risk of electrical failures from foreign object debris (FOD) and metal whiskers.

Reduce the risk of dendrite formation / electrochemical migration (ECM).

Minimize water absorption in humid environments

Improved Reliability

Impart low stress to solder joints, especially during thermal cycling

Very low levels of outgassing, critical for satellite and extreme remote sensing applications.

A low history of service needed in high-reliability apps, such as aerospace, defense, and medical devices.

Promote the durability of products, uptime, and employee and consumer safety.

Parylene Coatings at the Core of Trusted Products

How HZO helped Sarcos Robotics build their brand with Parylene-protected products.

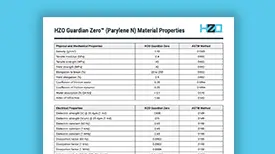

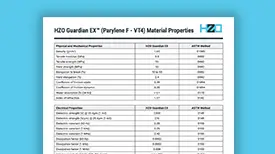

Parylene Properties

Parylene films have excellent properties. They have high dielectric performance. They resist abrasion and chemicals and have low thermal expansion.

Parylene's chemical vapor deposition (CVD) process produces pinhole-free coatings. They have a consistent thickness and true conformality.

The polymerization process has no initiators or catalysts. So, the coating is free from trace ionic impurities. It is also compliant with REACH, RoHS, and California Proposition 65. It is free of PFOA and PFOS.

The HZO Difference

See how HZO helped Prismview achieve 2X protection with 99% yield quality.

- Insoluble to common chemicals and conditions

- Superior barriers to moisture and chemicals

- Complete conformality on all exposed surfaces, corners, and edges

- Defect-free

- Free of solvents, residues, and catalysts

- Dry film lubricity

- High Dielectric Strength

- No outgassing

- No curing

- No thermal stress

- Optically clear and colorless

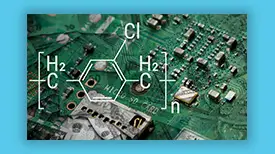

Parylene Types and Uses

Parylene has several types, each with unique properties. There is a Parylene for almost any application. Parylene types include:

Parylene F-VT-4 – Parylene F-VT-4 is highly crystalline. It has an excellent dielectric and very low friction coefficient. It is ideal for applications exposed to high temperatures.

Parylene N – Parylene N is an excellent dielectric. It is halogen-free and suitable for applications where sustainability is a priority.

Parylene C – Parylene C is the most used. It has the lowest permeability to moisture and gas, making it ideal for parts exposed to corrosive substances.

Advantages of Various Parylene Types

| ATTRIBUTES | PARYLENE C | PARYLENE N | PARYLENE F (VT-4) | Parylene F (AF-4) |

|---|---|---|---|---|

|

High submersion protection - IPX8+, also depends on device design.

|

|

|

|

|

|

Uniform, pinhole free coating.

|

|

|

|

|

|

High barrier protection against corrosive chemicals and gases. Low permeability to moisture. Best barrier when compared to the other Parylene types.

|

|

|

|

|

|

Optically transparent and can be used to coat optical elements.

|

|

|

|

|

|

Biostable, biocompatible, environmentally friendly — no VOCs, no solvents.

|

|

|

|

|

|

No initiators or catalysts in the polymerization process. The coating is pure and free from trace ionic impurities.

|

|

|

|

|

|

REACH, RoHS, PFOA/PFOS-free and CA Prop 65 compliant.

|

|

|

|

|

|

Room temperature formation makes the coatings effectively stress-free.

|

|

|

|

|

|

Low dielectric constant with good high frequency properties, good dielectric strength and high bulk and surface resistance.

|

|

|

|

|

|

High tensile strength.

|

|

|

|

|

|

No cure time.

|

|

|

|

|

|

Vibration resistant.

|

|

|

|

|

|

No pooling of coating in low areas.

|

|

|

|

|

|

Halogen free.

|

|

|

|

|

|

Free from bromine and chlorine halogens; contains fluorine.

|

|

|

|

|

|

Higher resistance to heat than Parylene C and N.

|

|

|

|

|

|

Highest temperature and UV resistant Parylene.

|

|

|

|

|

"Working with HZO has been invaluable to us. We can now produce reliable outdoor LED (Light Emitting Diode) signage performance that our customers around the world can depend on."

Donald Szczepaniak

Chief Executive Officer | PRISMVIEW, A Samsung Electronics Company

FAQ

How Much Does Parylene Cost?

We can't determine the cost of Parylene coatings without consulting our engineers. But, pricing generally depends on coating thickness, product complexity, and batch sizes.

Fill Out Quote Form to Get a Price Estimate

Consider the Total Cost of Ownership and Other Factors

The upfront pricing of coating is not indicative of the lifetime value of Parylene. We must weigh the coating's cost against its end-use and failure risks. As such, Parylene is cost-competitive with other high-quality coatings and lowers the overall total cost of ownership.

Read more about Parylene price considerations

How Much Time Does it Take to Incorporate Parylene into my Process?

When you work with HZO, we can quickly set up a Parylene coating process. We'll get you up and running soon. Every application is unique, so needs vary. But, the image below shows a typical timeline.

HZO PARYLENE PROCESS

PRE-PRODUCTION

Masking areas where protection is not needed can be fully or semi-automated. The Parylene experts at HZO can also manually mask your parts.

What is the Benefit of Working with a Parylene Coating Company?

Integrating Parylene into your production process is complex. It can be a time-consuming task if you try to do it alone. You must ensure your PCBs are suitable for the CVD process. Then, find the best method to mask and demask for Parylene. Finally, ensure proper surface preparation. Also, consider inspection, reworking, and repairing, plus, the manufacturing floor and process flow. So coating on your own is possible, but it may be more cost-effective to use a Parylene service provider.

Why HZO?

People

Our engineers understand what it means to put your project in their hands. With their domain experience and materials science expertise, they will partner with your team to find a solution.

Convenience

Our Parylene coating process can be quickly assembled in many settings. It is highly configurable. We offer many business models for your convenience. They include factory-in-factory (FiF) and coating-as-a-service (CaaS). This lets your team focus on what it does best: innovating products.

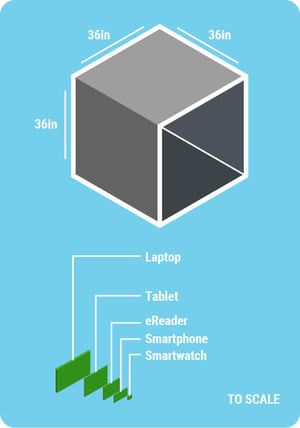

Our industry-leading automated and semi-automated masking equipment reduces labor hours associated with complex masking jobs.

Because of our unique benefits, we can serve customers in markets requiring scalability, faster production, and lower costs. With our help, engineers developing consumer electronics (such as a personal computer) and wearable medical devices have benefited from “Total Coating Solutions” and Parylene’s superior protection capabilities.

How Do I Get Started With Parylene Services?

Have a question or a problem? We have a solution. There are many ways to get started with Parylene services with HZO. You can send us a message (fill out the form) or request a quote to speak to one of our application engineers about specific applications.

Additional Resources

Learn About Parylene Properties With Our Resource Page

Learn How To Incorporate Conformal Coating Into Your Manufacturing Process

Learn About the Thin Film Coating Properties and Processes In Our Webinar

Learn How to Bring Parylene Deposition In-House