How Much Does Parylene Coating Cost? - All Things Considered

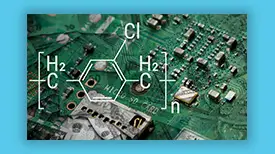

Parylene coatings are known for robust protection from liquids, corrosion, chemicals, and strong electrical activity at a fraction of the thickness of alternative coatings, such as acrylics, epoxies, silicones, and urethanes. Additionally, Parylene is biocompatible, with beneficial optical properties, and delivers superior protection at 50% thickness of conventional coatings, such as acrylic conformal coating or epoxy. But, Parylene dimer and labor can be costly. So, design teams may hesitate to use them for high-reliability protection.

Read about why engineers choose Parylene.

Is Cost-Efficient Parylene Possible?

Many see Parylene coating as hard and costly to apply despite its proven performance. So, many assume it is suitable only for extreme, mission-critical situations. These include military, medical, and aviation applications.

What Are Other Common Misconceptions About Parylene?

- Reworking and removing Parylene is impossible

- Parylene coating equipment is too expensive and complicated to use

- Masking is too complex and time-consuming to bother with

- CVD coatings (chemical vapor deposition) entail long batch times. This raises labor costs and lowers throughput

These assumptions are unfounded. But Parylene coating is the most costly of all conformal coating options. So, choose a partner who can work within your budget. They should also help you estimate potential costs.

How to Calculate the Cost of Parylene

At HZO, we have crafted processes and procedures to cut the costs of Parylene coating. Yet, three factors are pertinent to the price regardless of whom you work with.

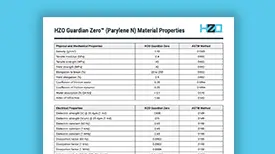

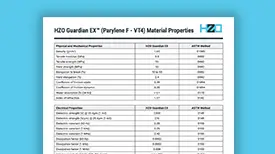

Parylene Type Affects the Cost

Common varieties, such as Parylene C and Parylene N, are less costly in raw coating material known as Parylene dimer. “Specialty types,” such as Parylene-AF4, will cost more but enable better UV and heat resistance. Consult HZO, a Parylene coating service, to find the best Parylene type for your project.

Parylene Masking Influences Price

Masking can be more complex with Parylene coatings, resulting in increased labor. However, changing your product's design can reduce costs. It would make it easier to coat and mask. HZO has industry-leading automated and semi-automated masking and demasking equipment. Working with us simplifies the process and cuts costs.

Quantity and Size of Objects that Require Coating

With Parylene, the objects you need to coat are placed into a vacuum chamber as part of the chemical vapor deposition (CVD) coating process. Each coating run will have a fixed cost. But, you can optimize the number of components coated in each run to lower the coating cost per item. (Meanwhile, HZO has built proprietary coating equipment that can house more items at once per run than any other Parylene company. This minimizes costs per run.)

Other Critical Considerations When Evaluating Parylene’s Price

Aside from considering upfront costs, to accurately assess Parylene’s coating expense, you must consider the coating’s value in terms of performance to preserve product function over time. In other words, the total cost of ownership is a critical consideration – upfront coating expense cannot fully measure value over a product’s life cycle. Parylene’s superior conformality and protection capabilities dramatically reduce field failures, warranty costs, and downtimes.

When you take the long-term view, the productivity and warranty savings that Parylene provides over time can make it the most economical coating option. There are other savings to consider when evaluating the price of conformal coatings, such as manufacturing costs. Conventional coatings entail cure cycles, VOC emissions, toxic byproducts, flammability, waste disposal, and health concerns. Parylene does not raise these safety and sustainability concerns as an environmentally friendly process.

Finally, investing in Parylene, with its exceptional dielectric strength, chemical and moisture resistance, and stress-free encapsulation, can substantially reduce the TCO to ruggedize components compared to other options.

Want to ensure HZO Parylene meets your specifications?

HZO Parylene Conformal Coating Services

If you want to evaluate Parylene coatings, contact our experts. They will provide a free DFM consultation.

Parylene Conformal Coatings - Parylene Conformality Explained

IoT - Coating Consistency is Key

Parylene Coating Removal - Methods & Best Practices for Each

Mallory is a veteran writer with over a decade of writing experience and has spent over five years at HZO learning about coating technology from the best minds in the industry. Professionally, Mallory is especially interested in the process of problem-solving and watching how the engineering team develops solutions that ensure business requirements are met. Over her years at HZO, Mallory's writing has been cited in industry whitepapers, including "Parabolic Model for Optimum Dry Film Thickness (DFT) of Corrosion Protective Coatings" and "Universal Approach to Integrating Reduced Graphene Oxide into Polymer Electronics." All of Mallory’s blogs are reviewed for accuracy before publication.

Additional Resources

Learn About Parylene Properties With Our Resource Page

Learn How To Incorporate Conformal Coating Into Your Manufacturing Process

Learn About the Thin Film Coating Properties and Processes In Our Webinar

Learn How to Bring Parylene Deposition In-House