INTERNET OF THINGS (IOT)

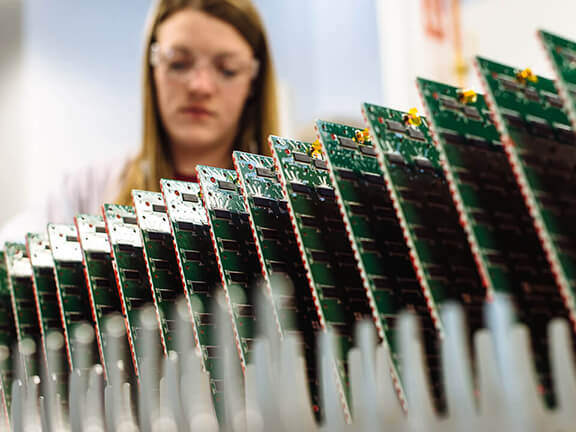

Robust Protection for IoT Sensors, Delivered with a Cost-Efficient, Scalable Turnkey Solution

Robust Protection for IoT Sensors, Delivered with a Cost-Efficient, Scalable Turnkey Solution

HZO coatings can sustain IoT sensors through full submersion, corrosive and hazardous operating environments at 50% thickness of conventional coatings.

Learn about other markets we serve.

Proven

Tested for over 1,200 hours of continuous submersion

Environment Protection

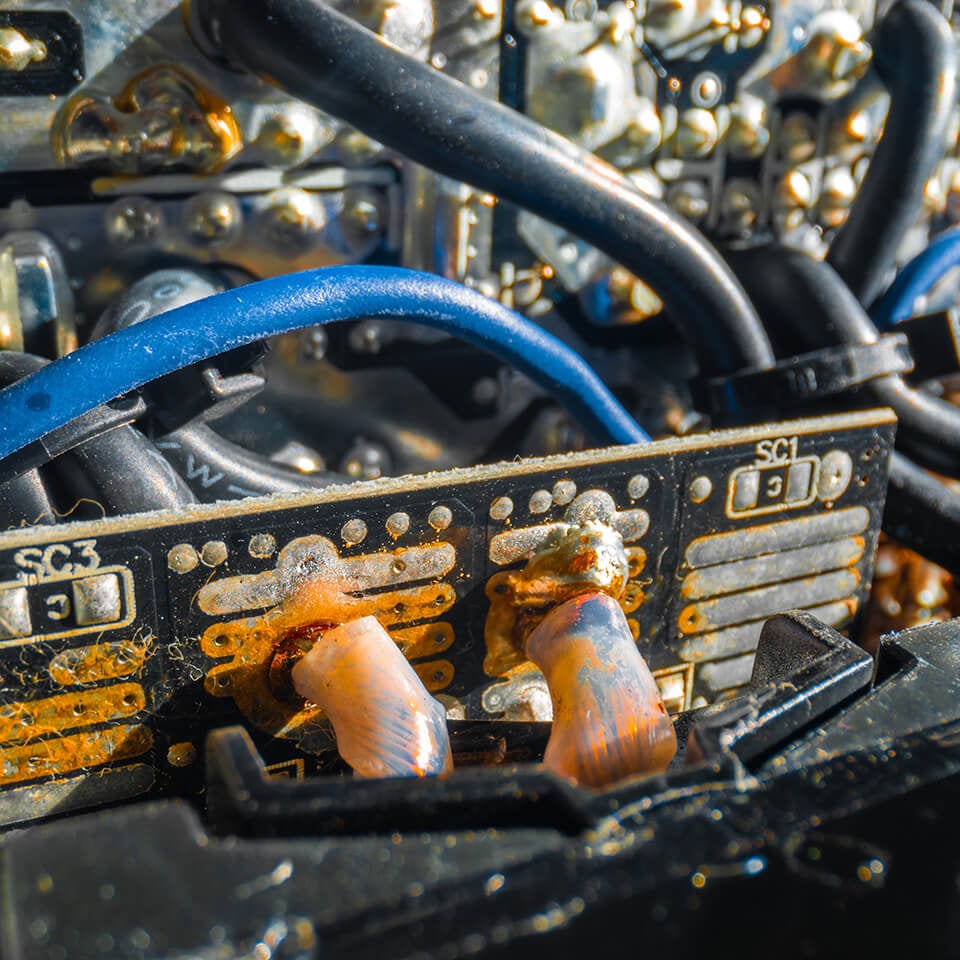

Superior Moisture Resistance and Corrosion Protection

Ruggedization for Corrosive Environments

HZO's Parylene WVTR and gas permeability properties are extremely low.

| Polymer | Gas Permeability at 25 °C, (cc·mm)/ (m2·day·atm) | WVTR (g·mm)/ (m2·day) |

||||||

| N2 | O2 | CO2 | H2 | H2S | SO2 | CI2 | ||

| Parylene C | 0.4 | 2.8 | 3.0 | 43.3 | 5.1 | 4.3 | 0.1 | 0.08 |

| Parylene N | 3.0 | 15.4 | 84.3 | 212.6 | 313 | 745 | 29.2 | 0.59 |

| Parylene D | 1.8 | 12.6 | 5.1 | - | 0.6 | 1.9 | 0.2 | 0.09 |

| Parylene F (VT-4) | - | 16.7 | - | - | - | - | - | 0.28 |

| Epoxy (ER) | 1.6 | 4 | 3.1 | 43.3 | - | - | - | 0.94 |

| Polyurethane (UR) | 31.5 | 78.7 | 1.81 | - | - | - | - | 0.93 |

| Silicone (SR) | - | 19,685 | 118,110 | 17,717 | - | - | - | - |

Barrier Protection for Resilient Products

Protect IoT components from:

DUST

HUMIDITY

CONDENSATION

OIL

Strong Chemical Resistance

Extremely resistant to solvents and reagents, including those listed below:

ACIDS, BASES, CORROSIVES

ORGANIC SOLVENTS

Hydrochloric acid, 10%

n-Octane

Sulfuric acid, 10%

n-Octane

Nitric acid, 10%

Chlorobenzene

Hydrofluoric acid, 10%

Pyridine

Sodium hydroxide solution, 10%

2-Propanol (IPA)

Ammonium hydroxide solution, 10%

Acetone

Hydrogen peroxide in water (H²O²)

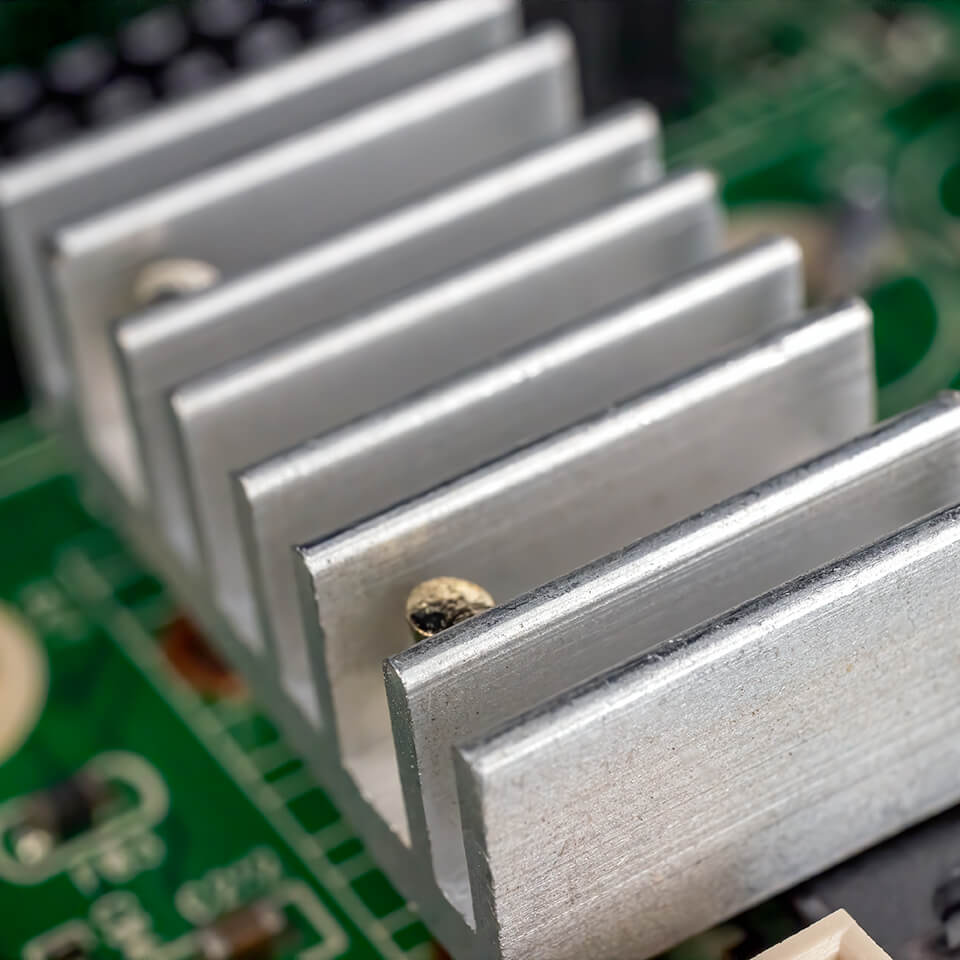

Beneficial Thermal Properties

HZO Coatings:

-

Can protect at temperatures up to 250°C

-

Allow for good heat dissipation

How HZO Coatings Protect IoT - Consistency is Key

Fully Functional Coating at Fraction of the Mass

HZO coatings pass IPC CC-830C test at 50% film thickness of other conformal coatings.

| THICKNESS (MICRONS) | 0.1 TO 5 | 5 TO 12.5 | 12.5 TO 25 | 12.5 TO 50.8 |

|---|---|---|---|---|

| Relevant Standards | UT Type in Upcoming IPC-CC-830C | UT Type in Upcoming IPC-CC-830C | IPC-CC-830B | NASA-STD-8739.1B |

| Protection Level | IPX3 / IPX4 | IPX4 / IPX7 | IPX7 / IPX8 | IPX7 / IPX8 |

| Appropriate Products | Consumer Electronic & MEMS Devices | Consumer & Industrial Electronics | Aerospace, Automotive, Industrial, Medical Device, Telecom, & Other High-Reliability Markets | Aerospace, Defense, & Very Harsh Industrial |

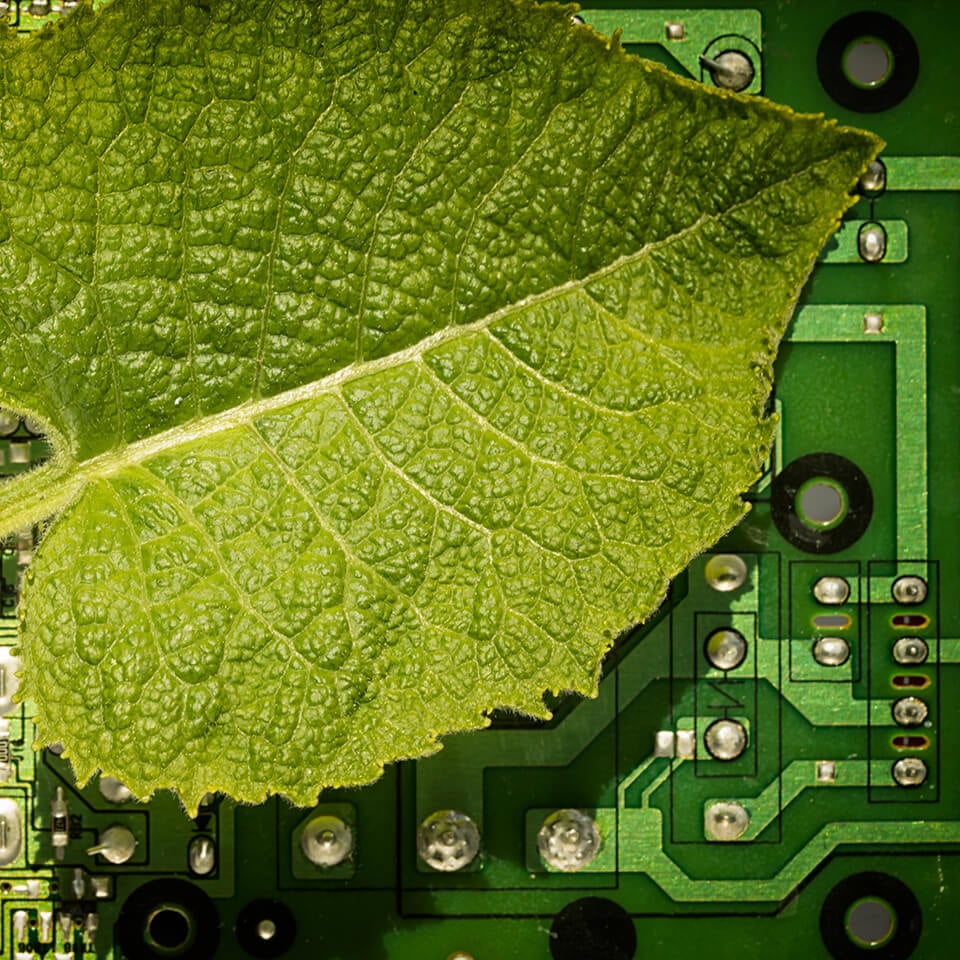

Sustainable Coatings Meet Regulation and Market Claims

ROHS COMPLIANT

REACH COMPLIANT

PROP 65 COMPLIANT

Select HZO Coatings have:

-

No VOCs

-

Biocompatible

-

No Catalysts

-

No Pollution Threats

-

No Cure Time

-

No Solvents

-

Biostable

-

No Halogens

-

No Disposal Issues

Cost-Effective, Scaleable, Convenient Solution

HZO Coating Process

1 Pre-Production

- Inspection for quality standards and control for product tracking.

- Assembly preparation takes place.

- Masking of areas where protection is not needed can be fully automated.

2 Production

- HZO raw material added to vaporizer and sublimated from solid to vapor form.

- Chemical is heated to a high temperature in a pyrolyzer, which "cracks" the raw material into an activated monomer.

- At room temperature in the coating chamber, vapor forms a uniform, thin-film polymer barrier around the PCBs.

Learn more about the CVD process.

3 Post-Production

- De-masking can be manual, semi-automated, or fully automated.

Flexibility and Expertise

-

Use a factory-in-factory business model or outsource to our global locations

-

Coating rework and removal expertise

Cost Savings

-

Masking automation supported by our IP portfolio reduces cost and labor

-

Automated, semi-automated, and manual masking available

Small Batch or Scale to High Volume

-

Throughput can be twice as fast as the industry standard

-

Specially designed equipment decreases turnaround time

Quality

-

Millions of components coated with zero product returns due to coating issues

-

Robust IQC / OQC process pre and post-coating

Download the HZO Parylene Datasheet

Resource Center

Webinar