INDUSTRIAL COATING

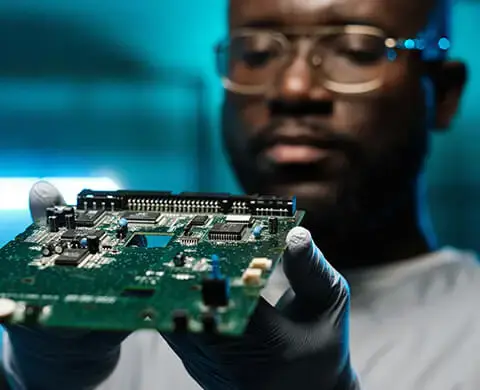

Deploy Industrial Devices That Can Operate and Transmit Signals Reliably in Harsh Environments

HZO coatings provide dielectric, corrosion, and chemical protection at 50% thickness of conventional coatings.

Dependable Device Operation

| ELECTRICAL PROPERTIES | HZO PARYLENE C | ASTM |

|---|---|---|

|

Dielectric strength (V) @25.4 μm (1 mil)

|

5,500

|

D149

|

|

Dielectric strength (V/μm) @25.4 μm (1 mil)

|

220

|

D149

|

|

Dielectric constant (60 Hz)

|

3.13

|

D150

|

|

Dielectric constant (1 kHz)

|

3.01

|

D150

|

|

Dielectric constant (1MHz)

|

2.92

|

D150

|

|

Dissipation factor (60 Hz)

|

0.022

|

D150

|

|

Dissipation factor (1 kHz)

|

0.017

|

D150

|

|

Dissipation factor (1MHz)

|

0.013

|

D150

|

|

Volume resistivity (23 °C, 50% RH, cm)

|

6.0 x 1016

|

D257

|

|

Surface resistivity (23 °C, 50% RH)

|

1.0 x 1015

|

D257

|

Electrical Properties Sustain Industrial Devices:

Corrosion and Full Immersion Protection:

-

Good high-frequency properties with low dielectric constant

-

High bulk and surface resistance

-

Provides insulation

-

Excellent dielectric strength

-

Water intrusion is not an issue

-

Tested for 1,000 hours of continuous submersion

-

Humidity resistant

-

Can meet any IP Rating

Chemical Resistance and Barrier Properties

HZO coatings protect components from:

HUMIDITY

OIL

DUST

SALT SPRAY

HZO Parylene coatings are resistant to solvent, strong acids, and inorganic reagents, including alkali.

Thin Coatings Facilitate Signal Transmittance

HZO has passed IPC CC-830C test at 50% of the film thickness of traditional conformal coatings.

| THICKNESS (MM) | 0.1 TO 5 | 5 to 12.5 | 12.5 to 25 | 13 to 51 |

|---|---|---|---|---|

|

Relevant Standards

|

UT Type in IP-CC-830C

|

UT Type in IPC-C-830C

|

IPC-CC-830B

|

NASA-STD-8739.1A

|

|

Protection Level

|

IPX3 / IPX4

|

IPX4 / IPX7

|

IPX7 / IPX8

|

IPX7 / IPX8

|

|

Appropriate Applications

|

Consumer Electronics & MEMS Devices

|

Consumer & Industrial Electronics

|

Aerospace, Automotive, Industrial, Medical Device, Telecom & Other High-Reliability Markets

|

Aerospace, Defense, & Very Harsh Industrial Applications

|

Meet Regulations and Market Claims

HZO coatings have:

NO VOCS

NO SOLVENTS

NO CATALYSTS

NO DISPOSAL ISSUES

NO POLLUTION THREATS

NO CURE TIME

BIOSTABLE

BIOCOMPATIBLE

Industrial Coating Applications

Have an application that isn't listed? Quickly find out if we can help.

Convenience:

-

Outsource to our global locations or use factory-in-factory business model

-

Dedicated engineers with market experience

-

Decrease turnaround time with our equipment designed in-house

-

Throughput can be two times faster than industry standard

Cost-Efficient:

-

Automated, Semi-automated, and Manual Masking Available to reduce labor and costs

-

Optimized equipment decreases coating runs

-

Processes in place to improve quality

-

Millions of components coated, no product returns attributed to coating issues

Additional Resources

Webinar

Learn About the Thin Film Coating Properties and Processes In Our Webinar

Brochure

Learn How to Make Your Industrial Product Design More Reliable

Technical Paper