Coating on Complex PCB Geometries

Video Transcript

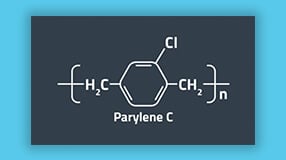

Well, when you get to coating these complex geometries, you gotta ask yourself how conformal do you need to be and how big are these different geometries that you're talking about? So are the parts really complex and have small, small little pieces on them, or are they just really large parts? I like to focus on the smaller parts that are really complex. Those are the things that we tend to excel at, especially in different coding techniques like PECVD.

00:40

And so if you look at the different type of coating techniques that we do here at HZO, there's a thermal CVD and there's just constraints in the reactors that we have for these techniques. For example, the thermal CVD reactor is about a meter cubed, so you can fit something that's really large in there if it's a physical dimension of one meter. A PECVD reactor that we have, because it's a capacitive coupled system, it's limited by how close your plates are.

01:10

fit something in between your two plates. And so generally things that are a height of 30 millimeters in the Z direction are okay to treat in there, but if you have something that's too large in the Z direction, then you have that limitation. But when you talk about like conformality of that part, really it depends on the technique that you're using. So I would say that an ALD technique is the best at conformality. So ALD.

01:36

Anywhere that you can have a gas absorbed to the side of the part, you'd be able to get a coating. But then as you go to thermal CVD, thermal CVD, you have to have gas diffusing in there, but it's also these atoms are activated by a thermal energy and as they get further away from that thermal source, they'll eventually react. So not quite line of sight, but it does. It's not as conformal as ALD. And then as you go to PECVD, so then you're activating your

02:05

your monomer and your atoms with the plasma, and you're also accelerating those ions toward the substrate. And so if you want to deposit something really fast, you're accelerating those fast. And then that can limit how conformal you're coating. Of course, there are some tunabilities in PECVD where you can accelerate things fast or slow, and you can make these multilayer coatings, which we actually do. And so to get...

02:31

If you want to get less conformal than PECVD and accelerate your ions even more, you'd go to a more of a PVD or sputtering technique. As you go to liquid coating and liquid dipping or liquid spraying, you can get less conformal because that liquid has to spread out as it dries and it doesn't really get in all the nooks and crannies. If you're thinking about deposition right, it's actually the opposite of this list. So you can get fastest deposition in a liquid dip.

03:00

and the slowest deposition in an ALD process. So if you want a really fast coating that's not very conformal, then a liquid would be the way to go, but that doesn't meet everyone's needs. Really we want something that's as conformal as an ALD, but we can deposit a lot faster. And that's somewhere in the middle ground with thermal CVD and PE CVD. Not just deposition rate is something to consider, but how much you're masking the part.

03:27

because in an ALD system that's really conformal, you'd have to mask everything that you don't want coded. While in a PECVD system, for example, you could use a shadow mask or something that's really close to the part, but doesn't have to have intimate contact. So I brought some parts here to give you some example of what I think of different geometries. And we have here in this first.

03:54

part just has some etched features in it. So these are some vias, some features that are anywhere from one micrometer to a hundred micrometers. And you can see that there's like a little rainbow pattern in there and that's how you can tell that there's different sizes and different thicknesses on here. This is what you'd see more like on a computer chip where there's lots of different small features. And these small features, to be able to coat them well, you need good conformality.

04:22

So if these features are underneath and around corners, you'd need an ALD type system. If they're more straight down in line of sight than a PCVD system would work and do fine. Now, the majority of things that we code are bigger than microchips. We generally wanna protect completed assemblies. And this is more of an example of a test board that has some flat features on it. And we coat these flat features.

04:51

There is only line of sight deposition needed on these parts. These are relatively easy to coat in some instances. So most of these techniques will work fine at coating this. As we get to more complex geometries using this Raspberry Pi, so this Raspberry Pi is pretty much a little computer. And we've coated it with a plasma process and made it to last in an IPX7 environment.

05:16

If you look at it closely, there's some rainbow patterning on here and that rainbow patterning kind of tells you how the different parts and the different materials on the board do affect the thickness of the film. The conformality isn't as good with PECVD as you would get with an ALD or thermal CVD. So in summary, a lot of scientists like to say that it depends, but it does. It really depends on what you're looking for. Do you want to coat something really conformal that has small complex geometries?

05:45

or you're looking to coat something that's really large. And we have techniques that handle both large items that can deposit really conformally. And also we can get down to faster deposition methods and coat things that have small features, but still get good conformality out of them. Yeah, thanks for taking the time to ask me these questions. I know I'm interested in them.

Are HZO Protection

Solutions Right for You?

Additional Resources

Learn About HZO's Partnership With a Fortune 100 Consumer Electronics Company