Designing a Waterproof Product With IP Ratings

The Big Picture: Manufacturers determine IP ratings, not an impartial group. Although these rating systems are useful for comparison purposes, they are not the panacea for rating electronic waterproof design.

If you are designing a waterproof product and using IP ratings as a measuring stick, you may want to reconsider. When people think about IP ratings, what they normally understand as “waterproof” are IPX5, IPX6, IPX7, and IPX8. However, this is a misrepresentation. So why do we use IP ratings to measure the amount of liquid protection a device has?

Do IP Standards Measure Liquid Protection, or Are They Just a Marketing Measure?

Consumers have been demanding waterproof electronics for a while now, and in the past, manufacturing marketing teams were happy to deliver what they didn’t necessarily have. Marketing teams, particularly for watches, showcased the word “waterproof” in their messaging. But these watches couldn’t stand up to liquid submersion.

In an attempt to clear the confusion, the International Organization for Standardization (ISO) replaced the word “waterproof” with “water-resistant This happened in 1990 when ISO issued the standard ISO 2281 for water-resistant products.

Nevertheless, a few years ago, commercials appeared with people using electronics in the shower, swimming with them in the pool, and dropping devices in the water – electronics, like smartphones, which, again, weren’t waterproof.

However, these commercials naturally led to the belief that the advertised products were, in fact, waterproof. However, customers described dropping so-called “waterproof” electronics for as little as 5 seconds, only to witness instant device destruction. The icing on the cake was that many manufacturers refused to mitigate liquid damage in their warranties.

As you might have imagined,lawsuits ensued.ISO tried to clarify again when they replaced the ISO 2281 standard with ISO 22810 to update the content in 2010.

Now, the term “water-resistant” describes products and the testing protocols created by the International Electrotechnical Commission (IEC) and ISO. Let’s look at some of those protocols now to understand how “waterproof” IP-rated devices are.

Learn more about NEMA vs IP ratings

What’s the Equivalent of IP Rated?

The first thing to know about IP testing protocols is that testing uses pure water only in laboratory conditions while the device is powered off.

Additionally, IP ratings only test for very specific environments.

IP Ratings only test for very specific environments

- Relative humidity range – 20% to 75%

- Air pressure range – 86 KPa to 106 KPa

- Test samples should be completely new and clean.

- Recommended temperature range – 15 C to 35 C

After testing, manufacturers inspect their devices’ enclosures for water ingress. Some water can even enter an enclosure and pass IP testing – under the condition that the exposure to water does not interfere with device operation or jeopardize user safety.

Do IP Standards Hold Up To Real Life?

Below are the requisites manufacturers must meet to deem a device “IP protected.”

The IPX6 standard test confirms that a device has suitable protection against heavy seas or powerful jets of water.

The IPX7 test attempts to determine whether electronic enclosures can provide enough protection from temporary immersion in water. A device will be immersed in water for a half-hour. The temperature of the product and the water cannot vary more than 5 C.

IPX8 tests for continuous immersion are completely subject to the manufacturer’s requisites. At the very least, they should be more severe than IPX7 conditions.

So, if you submerge a product from the box into 1 meter of fresh water inside a laboratory, your bases are covered. But what happens when you step outside the lab?

Learn about other standards, like Mil-i-46058c and UL94 ratings

The IP Rating System Won’t Help When Life Happens

There are a few glaring problems when it comes to calling an IP-rated device “waterproof” in real-life scenarios:

- Device pressure is affected by how it enters the water for IPX7 and IPX8 tests. Fluctuations in pressure can affect the depth and time a product can be submerged in water.

- Temperatures in bathrooms, bathtubs, steam rooms, or saunas will probably exceed the specific temperature range that manufacturers test for, making the physical seals meant to protect electronics less efficient at protecting the device.

- The tests use fresh water. Freshwater starkly contrasts the water that devices typically encounter, like tap water, swimming pools, saltwater, bathtubs, or toilets.

- Chemicals commonly used, like perfumes, oils, hair dyes, and solvents, can eat away at the mechanical parts and seals protecting a product, dragging the water-resistance level down.

- The fact that a device can be placed under 1 meter of water is great, but in the real world, products will probably fall to the bottom, voiding the guarantee that water will not ingress.

- The devices don’t have to be on during testing – if an electronic device is powered on underwater and is running programs, its internal temperature and pressure will increase, negatively affecting the depth of water the product can withstand.

Learn about hydrophilic coatings

How to Design a Truly Waterproof Electronic Device

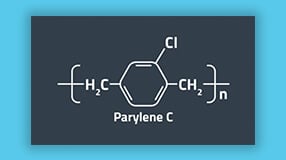

If you want a waterproof (not “water-resistant”) device, you needParylene conformal coating. As we explained above, commonly used mechanical seals don’t cut it.

Parylene is a polymer that coats the circuit boards powering your devices from the inside out. It doesn’t add thickness or bulk to devices that other conformal coatings do, and our Parylene can nullify water damage and last up to 20 years. You can learn more about Parylene and our Parylene coating process here.

Learn more about our coatings

Not All Devices HAVE to be Completely Waterproof

Although the IP rating standards are nebulous, they’re still useful for comparison, and many manufacturers require IP testing for devices that aren’t completely mission-critical. That’s why plasma-based nano coatings are sought out by engineers looking for affordable, ultra-thin conformal coating – they can meet any IP rating reliably and with scale.

But we digress. So, is IP57 waterproof? The answer is no; it is just water-resistant. When you consider your mission-critical waterproof electronic design, remember that you aren’t building products for a lab; you’re building products for life on life’s terms.

What is the Index of Refraction? Measurement, Definition & More

NEMA vs IP Ratings Explained

IP Ratings Decoded: IP57, IPX7, IPX5 Explained

Mallory is a veteran writer with over a decade of writing experience and has spent over five years at HZO learning about coating technology from the best minds in the industry. Professionally, Mallory is especially interested in the process of problem-solving and watching how the engineering team develops solutions that ensure business requirements are met. Over her years at HZO, Mallory's writing has been cited in industry whitepapers, including "Parabolic Model for Optimum Dry Film Thickness (DFT) of Corrosion Protective Coatings" and "Universal Approach to Integrating Reduced Graphene Oxide into Polymer Electronics." All of Mallory’s blogs are reviewed for accuracy before publication.

Additional Resources

Understand the Capabilities of Thin Film Coatings With Our Resource Page

Understand UL94 Rating - Testing, How to Choose a Material, and More

What's the Difference Between Hydrophobic Coatings and Hydrophilic Coatings?

Dielectric Constant of Insulator - Materials, Formula, Table of Values

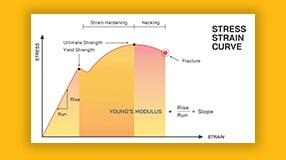

Tensile Strength at Yield - Testing, Definition, Material Selection

Young's Modulus of Polymers - Measurement, Calculation, Material Selection

Volume Resistivity - Definition, Measurement, Implications For Product Design

Polymer Glass Transition Temperature – Material Properties, Impact

What is Coefficient of Linear Expansion? Formula, Units & More

Learn About the Thin Film Coating Properties and Processes In Our Webinar

The Difference Between "Hydrophilic and Hydrophobic" Coating Properties

Learn about Protective Coating Methodologies With Our White Paper