Elongation Yield: Overview, Unit of Measure, Data and Testing

Elongation yield refers to the maximum amount of deformation a material can undergo before it experiences a permanent change in shape or size. This property is fundamental in determining various coating materials' mechanical strength and behavior, making it an essential factor in design engineering and product design.

Understanding how this property affects material performance is crucial in determining the suitability of coating material for a particular application. It directly affects the material's ability to deform without breaking and sustain loads without failure. This high-level overview will discuss elongation yield and its implications for product design.

Elongation Yield: Material and Unit of Measure

Elongation yield can be measured in various coating materials, including metals, polymers, and composites. Coating materials such as metals with higher values typically exhibit greater ductility, the measure of a material's ability to deform before fracture.

On the other hand, coating materials with a lower elongation yield tend to be less ductile and more prone to brittle behavior. They have limited ability to deform before reaching their breaking point. Such materials are usually more suitable for applications that require high strength and rigidity but not necessarily significant deformation.

Polymers, including plastics and rubber, display higher values than metals, enabling them to withstand extensive stretching or bending before breaking.

Composites, which consist of two or more different material components, can possess varying characteristics depending on their composition. The individual materials within a composite can have different abilities to undergo elongation yield, making the overall behavior complex.

Unit of Measure

Two standard units of measure are used to quantify elongation yield: percentage and millimeters.

The percentage unit of measure represents the elongation yield as a percentage of the original length of the material. For example, if a metal specimen stretches 10% before breaking, it has elongated by 10% of its original length.

On the other hand, millimeters are used to measure the actual physical elongation of a material. This unit of measure provides a more tangible representation of the deformation a material undergoes before reaching its breaking point.

Both units of measure have their advantages and are suitable for different applications. The choice between percentage and millimeters depends on the material type, testing specifications, and industry standards.

Data and Testing Method for Measuring

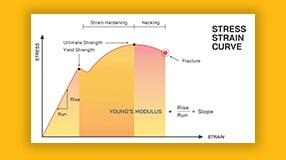

When determining a material's elongation yield, reliable data and thorough testing methods are essential to ensure accurate measurements and a deeper understanding of how a material will perform under various conditions. The data obtained during material testing provides valuable insights into the behavior of a material and its elongation yield. It includes measurements such as strain and stress, which calculate values.

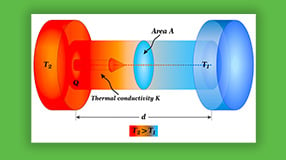

- Strain refers to the deformation experienced by a material when subjected to external forces. It is measured as the change in length divided by the original length.

- Stress is the force applied per unit area and is assessed by dividing the applied force by the original cross-sectional area.

By analyzing the relationship between stress and strain, engineers can identify the point at which the material starts deforming permanently, known as the elongation yield point.

Overview of the Different Testing Methods Used

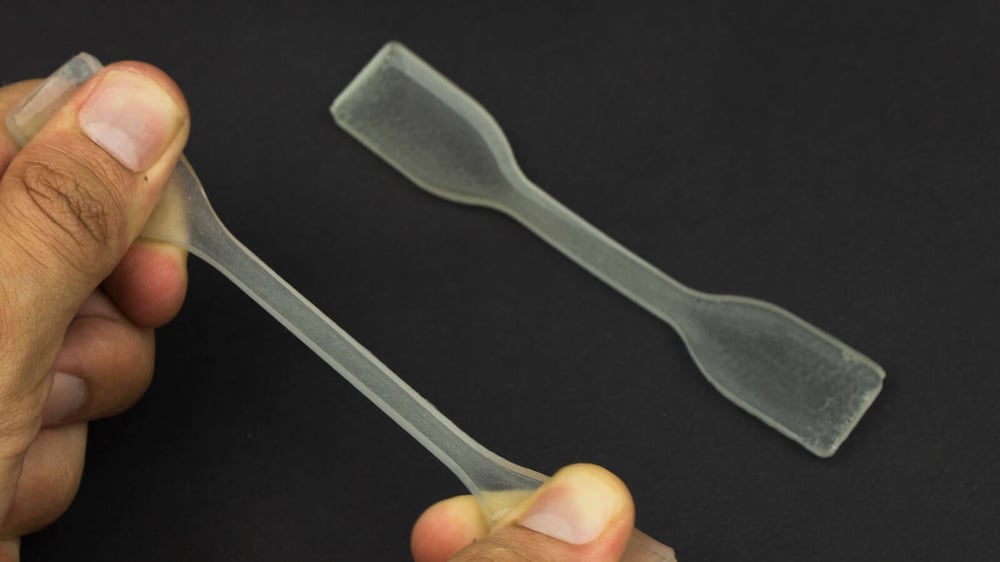

Various testing methods are employed to measure this property, each offering advantages and limitations. Tensile testing, for example, is commonly used to evaluate a material's mechanical properties, including elongation yield.

In tensile testing, a material sample is subjected to controlled tension until it reaches its elongation yield point. The resulting data helps determine the material's ability to withstand loads and deformations.

On the other hand, impact testing measures the energy absorbed by a material when it fractures under sudden stresses. This method provides valuable insights into the material's toughness and resistance to sudden impacts.

Other testing techniques, such as bend and hardness tests, can also provide insights. The bend test involves subjecting a material to bending forces to determine its flexibility and resistance to deformation. On the other hand, the hardness test measures the material's resistance to indentation, indirectly indicating its elastic deformation capabilities.

Specific standards established by regulatory bodies and industry organizations govern the testing procedures. These standards ensure consistency and comparability of test results across different laboratories and manufacturers.

Importance in Material Selection and Design

Engineers and designers can make informed decisions regarding coating material by considering the elongation yield. They can determine the material's capacity to stretch and deform before reaching its breaking point, safeguarding the reliability of the end product.

Moreover, understanding the elongation yield can also help optimize designs, reduce material waste, and enhance overall efficiency. Engineers can create designs that balance strength, flexibility, and cost-effectiveness by accurately predicting the coating material's behavior based on elongation yield values.

Electronic product reliability hinges on protective coating durability. If a coating breaks in any way, it could open the door to corrosives, chemicals, and other contaminants that could cause electronics to stop working. Therefore, understanding the elongation yield value is vital in ensuring electronic products' safety, durability, and performance in real-world applications. If you need help identifying the best coating material for your application, please contact our Applications engineers for a DFM consult. Alternatively, you can learn more about our coating protection capabilities, including Young's modulus, elongation at break, and tensile strength at yield.

What is the Index of Refraction? Measurement, Definition & More

Biocompatible Coatings - Coating Techniques, Applications, More

UL94 Coating Material - Testing Method, Material Selection

Mallory is a veteran writer with over a decade of writing experience and has spent over five years at HZO learning about coating technology from the best minds in the industry. Professionally, Mallory is especially interested in the process of problem-solving and watching how the engineering team develops solutions that ensure business requirements are met. Over her years at HZO, Mallory's writing has been cited in industry whitepapers, including "Parabolic Model for Optimum Dry Film Thickness (DFT) of Corrosion Protective Coatings" and "Universal Approach to Integrating Reduced Graphene Oxide into Polymer Electronics." All of Mallory’s blogs are reviewed for accuracy before publication.

Additional Resources

Understand the Capabilities of Thin Film Coatings With Our Resource Page

Understand UL94 Rating - Testing, How to Choose a Material, and More

What's the Difference Between Hydrophobic Coatings and Hydrophilic Coatings?

Dielectric Constant of Insulator - Materials, Formula, Table of Values

Tensile Strength at Yield - Testing, Definition, Material Selection

Young's Modulus of Polymers - Measurement, Calculation, Material Selection

Volume Resistivity - Definition, Measurement, Implications For Product Design

Polymer Glass Transition Temperature – Material Properties, Impact

What is Coefficient of Linear Expansion? Formula, Units & More

Learn About the Thin Film Coating Properties and Processes In Our Webinar

The Difference Between "Hydrophilic and Hydrophobic" Coating Properties

Learn about Protective Coating Methodologies With Our White Paper