Polymer Glass Transition Temperature - Material Properties, Impact

Polymer glass transition temperature (Tg) refers to the temperature at which an amorphous polymer transitions from a glassy, rigid state to a rubbery, flexible state. Understanding the polymer glass transition temperature is crucial for various industries, including engineering and manufacturing. The Tg provides valuable insights into a polymer's behavior, such as its processing, mechanical, thermal, and overall performance characteristics.

The polymer's structure, molecular weight, chemical composition, and branching influence the glass transition temperature. The Tg affects properties like stiffness, impact resistance, thermal stability, and transparency. Design engineers can optimize material selection, processing conditions, and performance requirements by understanding how the Tg relates to polymer structure.

Basics of Glass Transition

The glass transition is a phenomenon that occurs in amorphous polymers where the material changes from a rigid and brittle state to a softer and more flexible state when certain temperature conditions are met.

Several factors can affect the glass transition temperature (Tg) of polymers:

- Molecular weight and chain length: Polymers with higher molecular weights and longer chain lengths tend to have higher Tg values.

- Chemical structure and composition: Different chemical structures and compositions can result in variations in Tg values.

- Presence of plasticizers or additives: Plasticizers and additives can lower the Tg of polymers, making them more flexible and less brittle.

- Crystallinity or amorphous nature of the polymer: Amorphous polymers generally have lower Tg values than crystalline polymers.

Influence of Glass Transition Temperature on Polymer Properties

A polymer's glass transition temperature (Tg) plays a crucial role in determining its properties and performance. This temperature marks the transition from the glassy state to the rubbery state, where the polymer undergoes significant changes in its physical and mechanical behavior.

Impact on mechanical properties

The glass transition temperature has a profound effect on various mechanical properties of polymers, such as:

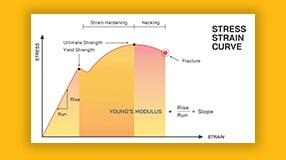

- Tensile strength: The Tg of a polymer can influence its tensile strength. Polymers with a higher Tg tend to have higher tensile strength, as the increased molecular mobility at elevated temperatures allows for better alignment and bonding.

- Elastic modulus: The Tg also affects the elastic modulus, which refers to a material's ability to resist deformation. Polymers with a higher Tg typically exhibit a higher elastic modulus, indicating greater stiffness and rigidity.

- Impact resistance: The Tg can impact the impact resistance of polymers. As the Tg increases, the polymer becomes more brittle and prone to fracture upon impact. On the other hand, polymers with lower Tg values exhibit better impact resistance and toughness.

Effect on thermal behavior

The glass transition temperature has significant implications for the thermal behavior of polymers:

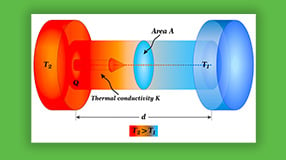

- Melting temperature and thermal conductivity: The Tg influences the melting temperature of a polymer. Polymers with higher Tg values generally have higher melting temperatures. Additionally, a higher Tg can result in lower thermal conductivity, which affects the material's ability to transfer heat.

- Heat resistance and aging: The Tg indicates a polymer's heat resistance. Polymers with high Tg values exhibit better heat resistance and are less prone to degradation at elevated temperatures. Furthermore, understanding the Tg is crucial for predicting the long-term aging behavior of a polymer in various environmental conditions.

Temperature-Dependent Polymer Properties

Temperature plays a crucial role in determining the properties of polymers. As the temperature changes, various characteristics of polymers undergo significant transformations. Understanding the temperature-dependent behavior of polymers is essential for a wide range of applications, from material selection to manufacturing processes.

Changes in Polymer Properties with Temperature Variations

When exposed to different temperatures, polymers exhibit distinct alterations in their properties. These variations include changes in mechanical strength, electrical conductivity, chemical resistance, and dimensional stability. For example, as the temperature rises, the mechanical strength of a polymer tends to decrease due to increased molecular motion.

Relationship Between Glass Transition Temperature and Other Temperature-Dependent Properties

Glass transition temperature has a relationship with other temperature-dependent properties, including:

- Specific heat capacity: The glass transition temperature of a polymer is closely related to its specific heat capacity, which is the amount of heat required to raise the temperature of a unit mass of the material by a certain degree. Understanding this relationship is essential for predicting polymers' heat absorption and release capabilities at different temperatures.

- Coefficient of thermal expansion: The coefficient of thermal expansion measures the extent to which a material expands or contracts when subjected to temperature changes. The glass transition temperature considerably influences the coefficient of thermal expansion of polymers. Higher glass transition temperatures generally result in lower coefficients, indicating reduced dimensional change with temperature.

- Viscosity and flow behavior: As the temperature varies, polymers experience viscosity and flow behavior changes. Polymers act as rigid solids with high viscosity at temperatures below the glass transition temperature. However, as the temperature surpasses the glass transition temperature, polymers transition into a more flexible state, exhibiting lower viscosity and increased flow characteristics.

Measurement and Determination of Values

Obtaining accurate glass transition temperature data is essential. Several experimental techniques may be employed for measurement, including:

- Differential Scanning Calorimetry (DSC): DSC is a widely used technique that measures the heat transfer in a sample as it goes through a glass transition. It provides information about the glass transition temperature and the enthalpy of transition.

- Dynamic Mechanical Analysis (DMA): DMA measures the mechanical properties of a sample as a function of temperature or frequency. It can provide information about the glass transition temperature by observing changes in the sample's modulus, damping, and storage modulus.

- Thermomechanical Analysis (TMA): TMA measures the dimensional changes of a sample as a function of temperature or time. It can determine the glass transition temperature by monitoring changes in the sample's dimensions.

- Fourier Transform Infrared Spectroscopy (FTIR): FTIR measures a sample's absorption of infrared light. Analyzing the changes in the infrared spectra of the sample as a function of temperature can determine the glass transition temperature.

Factors influencing the accuracy and repeatability of glass transition temperature measurements

Several factors influence the accuracy and repeatability of glass transition temperature measurements, such as:

- Heating and cooling rates: The rate at which the sample is heated or cooled can affect the observed glass transition temperature. Different heating and cooling rates can lead to variations in the measured value.

- Sample preparation and handling: How the sample is prepared and handled before the measurement can also impact the glass transition temperature. Contamination or improper handling can introduce errors.

- Physical state of the polymer (solid, liquid, or semi-solid): The physical state of the polymer can affect the glass transition temperature measurement. Different states can exhibit different glass transition temperatures.

- Presence of impurities or additives: Impurities or additives present in the polymer can influence the observed glass transition temperature. These substances can alter the polymer's molecular structure and affect its behavior during the glass transition.

Role in material applications

The glass transition temperature influences the choice of polymers in various industries and applications, including:

- Automotive and aerospace: The Tg of polymers used in automotive and aerospace applications is critical, as it determines their ability to withstand high-temperature environments and maintain dimensional stability.

- Consumer goods and electronics: The Tg influences the selection of polymers for consumer goods and electronic devices. Polymers with suitable Tg values are chosen to ensure durability, impact resistance, and resistance to heat and aging.

- Medical and healthcare sector: The Tg of polymers used in medical and healthcare applications is essential for ensuring biocompatibility, sterilizability, and resistance to various environmental factors.

This diverse range of applications highlights the glass transition temperature's crucial role in tailoring polymer properties to meet specific requirements. Contact our engineers if you need to choose a protective coating material with a particular glass transition temperature and require assistance or learn more about thin film protection capabilities, such as coefficient of linear expansion, thermal conductivity, or optical properties, such as refractive index or transparency.

Biocompatible Coatings - Coating Techniques, Applications, More

UL94 Coating Material - Testing Method, Material Selection

Dielectric Constant of Insulator Materials: Formula, Table of Values

Mallory is a veteran writer with over a decade of writing experience and has spent over five years at HZO learning about coating technology from the best minds in the industry. Professionally, Mallory is especially interested in the process of problem-solving and watching how the engineering team develops solutions that ensure business requirements are met. Over her years at HZO, Mallory's writing has been cited in industry whitepapers, including "Parabolic Model for Optimum Dry Film Thickness (DFT) of Corrosion Protective Coatings" and "Universal Approach to Integrating Reduced Graphene Oxide into Polymer Electronics." All of Mallory’s blogs are reviewed for accuracy before publication.

Additional Resources

Understand the Capabilities of Thin Film Coatings With Our Resource Page

Understand UL94 Rating - Testing, How to Choose a Material, and More

What's the Difference Between Hydrophobic Coatings and Hydrophilic Coatings?

Dielectric Constant of Insulator - Materials, Formula, Table of Values

Tensile Strength at Yield - Testing, Definition, Material Selection

Young's Modulus of Polymers - Measurement, Calculation, Material Selection

Volume Resistivity - Definition, Measurement, Implications For Product Design

Polymer Glass Transition Temperature – Material Properties, Impact

What is Coefficient of Linear Expansion? Formula, Units & More

Learn About the Thin Film Coating Properties and Processes In Our Webinar

The Difference Between "Hydrophilic and Hydrophobic" Coating Properties

Learn about Protective Coating Methodologies With Our White Paper