Arc Resistance - Concepts and Testing Explained

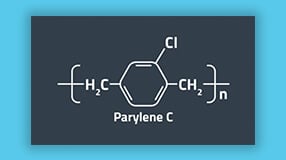

Insulating materials such as Teflon, plastic, rubber, ceramic, or glass ensure products function properly and safely. However, no insulator is perfect. These materials still contain trace amounts of mobile charges that can carry current. Non-conductive polymeric coatings provide critical protection to electronic components, but these materials can become conductive when electric current travels along their surfaces due to chemical and thermal decomposition and material erosion. Therefore, the arc resistance electric property is considered when selecting materials where reliable insulation is a priority.

Arc Resistance Definition

Arc resistance is defined as the ability of an insulating material to withstand a high voltage, low current arc and resist the development of a conducting pathway along its surface. More specifically, it measures the time in seconds an electrical arc may exist on an insulator’s surface before the material’s breakdown occurs.

Significance

This property is helpful as a design criterion to choose materials for situations vulnerable to electric arcing but serves other purposes, acting as:

- A quality control method

- A way to screen materials for applications susceptible to arcing

- Determining changes in insulation behavior due to aging, irradiation, exposure to temperature or humidity, chemical and thermal decomposition, contamination, and erosion

Arc Resistance Testing

The ASTM D495 test uses a high-voltage, low-current arc to simulate service conditions and evaluate dry, uncontaminated samples. According to the ASTM D945 arc resistance test, specimens are placed between electrodes, and an arc is generated at specified current densities and scheduled intervals. The total elapsed operation time until test failure determines a material’s arc resistance.

Several arc testers that comply with this test method are commercially available.

Test Methods ASTM D 2132, D 2303, and D 3638 entail wet testing with contaminated specimens.

How to Improve Arc Resistance

Differing molecular structures, formulation ingredients such as curing agents, and physical and chemical surface conditions cause arc resistances of coatings to vary widely. Fillers, such as glass or mineral fillers, can improve the arc resistance of polymer coatings, easily doubling or tripling the arc resistance of unfilled epoxy resin systems.

Additionally, resistance increases when the coating surface is kept dry and contaminant-free. Even touching the surface will reduce resistance due to moisture, oils, and salts transferred from the fingers.

Choosing The Right Coating

Not all coatings have exact arc resistance values due to issues with testing. Some crack, gum up, or melt during testing. When precise values that can be reproduced are acquired, they result from the material’s stability, purity, and surface cleanliness. If you need to evaluate material for a project, you can ask coating suppliers if an exact value is available.

Contact us or read about other critical electric thin film properties, such as volume resistivity or dissipation factor.

Biocompatible Coatings - Coating Techniques, Applications, More

What is the Index of Refraction? Measurement, Definition & More

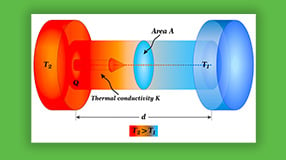

What is Thermal Conductivity? Explanation, Measurement, Uses

Mallory is a veteran writer with over a decade of writing experience and has spent over five years at HZO learning about coating technology from the best minds in the industry. Professionally, Mallory is especially interested in the process of problem-solving and watching how the engineering team develops solutions that ensure business requirements are met. Over her years at HZO, Mallory's writing has been cited in industry whitepapers, including "Parabolic Model for Optimum Dry Film Thickness (DFT) of Corrosion Protective Coatings" and "Universal Approach to Integrating Reduced Graphene Oxide into Polymer Electronics." All of Mallory’s blogs are reviewed for accuracy before publication.

Additional Resources

Understand the Capabilities of Thin Film Coatings With Our Resource Page

Understand UL94 Rating - Testing, How to Choose a Material, and More

What's the Difference Between Hydrophobic Coatings and Hydrophilic Coatings?

Dielectric Constant of Insulator - Materials, Formula, Table of Values

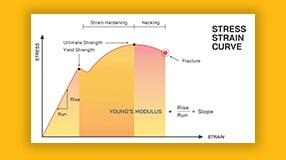

Tensile Strength at Yield - Testing, Definition, Material Selection

Young's Modulus of Polymers - Measurement, Calculation, Material Selection

Volume Resistivity - Definition, Measurement, Implications For Product Design

Polymer Glass Transition Temperature – Material Properties, Impact

What is Coefficient of Linear Expansion? Formula, Units & More

Learn About the Thin Film Coating Properties and Processes In Our Webinar

The Difference Between "Hydrophilic and Hydrophobic" Coating Properties

Learn about Protective Coating Methodologies With Our White Paper