Water Vapor Transmission Rate - Standards, Testing, Material

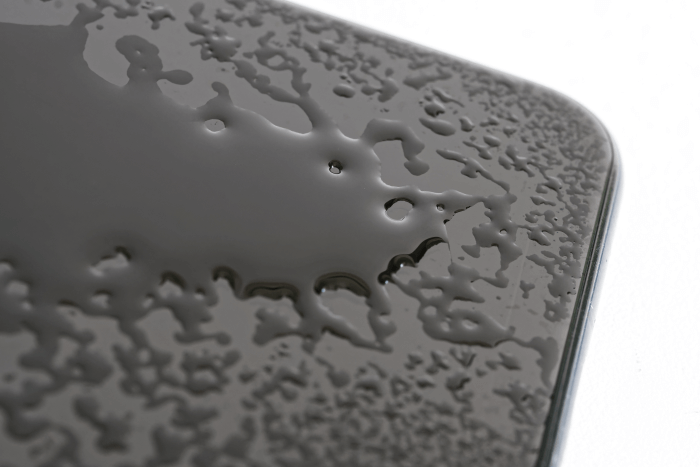

In the world of electronics, moisture control is of utmost importance. High water vapor transmission rate (WVTR) can pose significant risks to sensitive electronic devices. When moisture enters electronic components, it can lead to various issues, including corrosion, short circuits, and malfunctioning. These risks can result in costly repairs, product failures, and even safety hazards.

Manufacturers continually strive to create smaller, faster, and more powerful electronics. However, these advancements also often make the devices more susceptible to moisture damage. Implementing effective moisture control measures during the design and manufacturing process is essential to ensure the longevity and reliability of electronic components.

Water vapor transmission refers to the movement of water vapor through a material or substance. The water vapor transmission rate is a pivotal property for moisture control, and as such, measuring and managing WVTR is a priority in many applications.

Understanding Water Vapor, Transmission, and Vapor Transmission

Water vapor refers to the presence of water in a gaseous state. Under certain temperature and pressure conditions, water vapor can condense into liquid water.

Transmission refers to the movement of any substance, whether liquids, gases, or solids, from one side of a barrier to the other. This movement can occur through various means, such as diffusion, permeation, or evaporation. Vapor transmission, on the other hand, specifically relates to the movement of water vapor molecules through a barrier.

Vapor transmission plays a crucial role in moisture control. Without the ability for water vapor to move freely through materials, moisture can become trapped, leading to mold growth, structural damage, and product degradation. By allowing water vapor to escape, vapor transmission helps prevent excessive moisture buildup.

Factors affecting vapor transmission

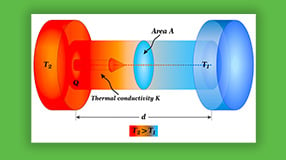

Several factors influence the rate of vapor transmission. These include temperature, pressure, and humidity.

- Temperature variations can affect the rate water molecules transition between vapor and liquid states. Higher temperatures generally increase the speed of vapor transmission.

- Pressure differentials between the two sides of a barrier can also impact vapor transmission. In some cases, pressure differentials can hinder or enhance the movement of water vapor.

- Humidity levels, which measure the amount of water vapor in the air, can greatly influence vapor transmission. Higher humidity often leads to higher vapor transmission rates, while lower humidity may restrict the movement of water vapor through materials.

Water Vapor Transmission Standards and Testing

The ASTM standards outline the procedures and techniques for conducting WVTR tests, ensuring consistency and accuracy across different laboratories and testing facilities. These standards provide guidelines on sample preparation, test conditions, and data analysis, allowing for reliable and comparable results.

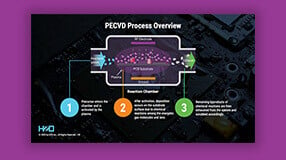

Overview of Permeability Testing Methods and Techniques

Permeability testing refers to the evaluation of how easily water vapor can permeate through a material or film. Several methods are available to measure WVTR, including the gravimetric method, the desiccant method, and the electrical measurement method. Each method has its advantages and limitations, and the choice of method depends on factors such as the material being tested and the required accuracy. You can read more about these methods at the ASTM website.

Importance of Accurate Testing for Reliable WVTR Results

Accurate testing determines a material's true water vapor transmission rate. By following ASTM standards and utilizing appropriate testing methods, manufacturers can ensure that their products meet the necessary performance requirements and provide optimal moisture control.

Learn about relevant standards such as Ingress Protection Standards and NEMA Ratings.

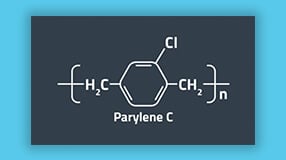

Film and Polymer Materials

Thin films play integral roles in creating effective moisture barrier systems. These materials are designed to prevent water vapor passage, thereby protecting products and structures from moisture damage.

Specific properties and characteristics become priorities when evaluating coating materials for moisture control. Engineers should consider the following:

- Water vapor permeability: measures how easily water vapor can pass through a material. Lower permeability indicates better moisture resistance.

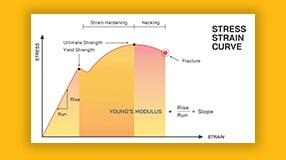

- Tensile strength: the ability of the coating material to resist breaking or tearing under tension

- Elongation at break: The maximum elongation or stretch a material can undergo before breaking. Higher elongation allows for flexibility and resistance to tearing.

- Chemical resistance: the resistance of the material to chemical substances, preventing degradation and maintaining its moisture control properties

- Transparency: In specific applications, it is essential for the polymer material to maintain transparency, allowing consumers to evaluate products visually.

If you need a coating material with a low water vapor transmission rate or have questions about choosing suitable materials, contact our Applications Engineers for a DFM consult. Or, you can learn more about protective thin film coating properties.

What is Thermal Conductivity? Explanation, Measurement, Uses

What is the Index of Refraction? Measurement, Definition & More

Biocompatible Coatings - Coating Techniques, Applications, More

Mallory is a veteran writer with over a decade of writing experience and has spent over five years at HZO learning about coating technology from the best minds in the industry. Professionally, Mallory is especially interested in the process of problem-solving and watching how the engineering team develops solutions that ensure business requirements are met. Over her years at HZO, Mallory's writing has been cited in industry whitepapers, including "Parabolic Model for Optimum Dry Film Thickness (DFT) of Corrosion Protective Coatings" and "Universal Approach to Integrating Reduced Graphene Oxide into Polymer Electronics." All of Mallory’s blogs are reviewed for accuracy before publication.

Additional Resources

Understand the Capabilities of Thin Film Coatings With Our Resource Page

Understand UL94 Rating - Testing, How to Choose a Material, and More

What's the Difference Between Hydrophobic Coatings and Hydrophilic Coatings?

Dielectric Constant of Insulator - Materials, Formula, Table of Values

Tensile Strength at Yield - Testing, Definition, Material Selection

Young's Modulus of Polymers - Measurement, Calculation, Material Selection

Volume Resistivity - Definition, Measurement, Implications For Product Design

Polymer Glass Transition Temperature – Material Properties, Impact

What is Coefficient of Linear Expansion? Formula, Units & More

Learn About the Thin Film Coating Properties and Processes In Our Webinar

The Difference Between "Hydrophilic and Hydrophobic" Coating Properties

Learn about Protective Coating Methodologies With Our White Paper