What is the Dielectric Strength Formula? Testing, Table of Values

Although thin film coatings serve many purposes, providing dielectric isolation and electrical insulation is one of the essential functions. Dielectric strength is an important electrical parameter that helps design engineers understand the effectiveness of a coating’s insulation resistance. It is helpful to be familiar with the exact electrical values for this property and to know how the values may be affected by environments, such as humidity and temperature, and purity, structure, and composition of the coating material.

Read more about electrical properties such as dissipation factor and dielectric constant of insulator materials.

What is Dielectric Strength, and Why is it Important?

Dielectric strength is a coating’s ability to endure an applied voltage without breakdown. This parameter is the highest voltage (typically stated in volts per mil thickness) at which no dielectric breakdown occurs. It quantifies how strong a conformal coating’s insulation is, with a higher number signifying the insulating material’s high resistance to dielectric breakdown.

Maintaining dielectric resistance is critical for impedance and signal integrity concerns, as the insulating material must keep the circuit working correctly. Enhancing dielectric strength protects the circuit board’s long-term function. The safety and effectiveness of a device with a circuit board rely on an entirely closed system, so insulation with high dielectric resistance is critical.

Additionally, PCB designs can be more compact when they feature a coating with increased dielectric strength. Integrating more capability into smaller form factors in the demanding electronics industry is crucial to staying ahead of the curve.

At both high and low voltages, dielectric considerations are particularly important for the reliability of electronic circuits.

Knowing the dielectric strength of a coating is critical for designing reliable electronics intended to operate at high voltages, as higher values represent a better insulator quality. If a coating is exposed to a voltage that causes breakdown, it will be rendered useless. Therefore, the data should be accurate – measured carefully to obtain reproducible results under specified conditions in a test.

Understand thin film properties in greater detail

Dielectric Strength Vs. Dielectric Breakdown Voltage Vs. Dielectric Constant – What is the Difference?

Dielectric breakdown voltage is the voltage threshold at which actual failure occurs. This value is also expressed in volts per mil thickness; these two terms are used interchangeably.

Dielectric strength and dielectric constant are both electrical properties. However, the former is the maximum voltage that can be applied to a material before it loses its insulating properties, and the dielectric constant is the capacity of a material to store electrical energy. These values are also expressed differently. Dielectric constant is a ratio with no units of measurement.

How is It Measured?

Several standard dielectric strength tests exist, including ASTM D149 and IPC-TM-650, Method 2.5.7. There are three basic procedures: the short-time method, the step-by-step method, and the slow rate-of-rise method. All these methods entail the same setup – a test specimen placed between two electrodes in oil or air.

In the short-time method, the most common test, voltage is applied across the two electrodes and raised to dielectric breakdown at a uniform rate. Breakdown is an electrical burn-through puncturing the specimen or decomposition in the sample.

Dielectric Strength Formula

With this test data, it is possible to calculate dielectric strength. The formula is to divide the breakdown voltage by the thickness of the sample. The value is reported in volts per mil thickness.

What Material Has High Dielectric Strength?

Organic coatings generally have much higher dielectric strength than inorganic or ceramic coatings. Materials that contain impurities, voids, and moisture will have lower breakdown voltages.

The table below shows the material dielectric strength of polymer conformal coatings.

| Conformal Coating Type | Dielectric Strength | Desired |

|---|---|---|

| Parylene N | 7000 | High |

| Parylene C | 5600 | High |

| Acrylic | 1200 | High |

| Epoxy | 900-1000 | High |

| Silicone | 1100-2000 | High |

| Urethane | 1400-3000 | High |

Source: Handbook of Plastics, Elastomers, and Composites, 4th Edition, McGraw Hill, Inc. New York, 2002. Chapter 6.

Why Do Insulating Coatings Break Down, and What Affects Dielectric Strength?

Even the most effective insulation materials contain a few free electrons and ions due to molecular imperfections or thermal agitation. The physical breakdown of the coatings is likely due to an electron “avalanche” effect (a large increase in electrons) within the coating. Several factors can affect this value. First, the thickness of the coating has an effect. Thinner coatings have higher values. A coating’s purity and physical integrity (lack of air void and pinholes) contribute to its effectiveness as an insulator. Dielectric strength decreases as impurities or imperfections increase. In terms of operating environments, exposure to moisture and elevated temperatures cause pronounced declines in values. In some instances, though, the final value is sufficiently high for most applications. To learn more about the electrical parameters of thin film coatings, read our protection capabilities page.

Tensile Strength at Yield - Testing, Standards, Specs, Material

UL94 Coating Material - Testing Method, Material Selection

Biocompatible Coatings - Coating Techniques, Applications, More

Mallory is a veteran writer with over a decade of writing experience and has spent over five years at HZO learning about coating technology from the best minds in the industry. Professionally, Mallory is especially interested in the process of problem-solving and watching how the engineering team develops solutions that ensure business requirements are met. Over her years at HZO, Mallory's writing has been cited in industry whitepapers, including "Parabolic Model for Optimum Dry Film Thickness (DFT) of Corrosion Protective Coatings" and "Universal Approach to Integrating Reduced Graphene Oxide into Polymer Electronics." All of Mallory’s blogs are reviewed for accuracy before publication.

Additional Resources

Understand the Capabilities of Thin Film Coatings With Our Resource Page

Understand UL94 Rating - Testing, How to Choose a Material, and More

What's the Difference Between Hydrophobic Coatings and Hydrophilic Coatings?

Dielectric Constant of Insulator - Materials, Formula, Table of Values

Tensile Strength at Yield - Testing, Definition, Material Selection

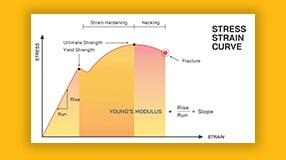

Young's Modulus of Polymers - Measurement, Calculation, Material Selection

Volume Resistivity - Definition, Measurement, Implications For Product Design

Polymer Glass Transition Temperature – Material Properties, Impact

What is Coefficient of Linear Expansion? Formula, Units & More

Learn About the Thin Film Coating Properties and Processes In Our Webinar

The Difference Between "Hydrophilic and Hydrophobic" Coating Properties

Learn about Protective Coating Methodologies With Our White Paper