TECHNICAL PAPER

Safeguarding Electrical Components and Products with Nanocoating Technology

About the Paper

Thin film nanocoatings protect critical electronic circuitry that is used in a variety of applications and can be a powerful solution to implement to ensure reliability. Learn more in HZO's white paper authored by engineers.

About the Infographic

In the auto industry alone, downtime can cost up to $3 million per hour. Downtime is bad enough, but the repercussions of unplanned downtime can be downright scary. Learn about the pitfalls and threats of downtime and how they can be avoided when it comes to protecting your electronic components with HZO coating technology.

Paper Highlights

-

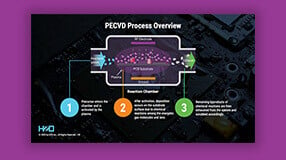

Plasma-enhanced chemical vapor deposition overview

-

Benefits of the PECVD process

-

Process diagrams and images of film coverage

-

HZO PECVD performance test results

-

IPX4 testing results and summary

Are HZO Protection

Solutions Right for You?

Additional Resources

Blog

What's the Difference Between Hydrophobic Coatings and Hydrophilic Coatings?

Video

The Difference Between "Hydrophilic and Hydrophobic" Coating Properties

Technical Paper