OTHER INDUSTRIES

Protective Coating Application Services with a Flexible Turnkey Solution

Our thin-film coatings have many beneficial features, including electric insulation, full immersion protection, and corrosion resistance.

FULL IMMERSION PROTECTION AND CORROSION RESISTANCE

Conformal Coating Barrier Properties

| Polymer | Gas Permeability at 25 °C, (cc·mm)/ (m2·day·atm) | WVTR (g·mm)/ (m2·day) |

||||||

| N2 | O2 | CO2 | H2 | H2S | SO2 | CI2 | ||

| Parylene C | 0.4 | 2.8 | 3.0 | 43.3 | 5.1 | 4.3 | 0.1 | 0.08 |

| Parylene N | 3.0 | 15.4 | 84.3 | 212.6 | 313 | 745 | 29.2 | 0.59 |

| Parylene D | 1.8 | 12.6 | 5.1 | - | 0.6 | 1.9 | 0.2 | 0.09 |

| Parylene F (VT-4) | - | 16.7 | - | - | - | - | - | 0.28 |

| Epoxy (ER) | 1.6 | 4 | 3.1 | 43.3 | - | - | - | 0.94 |

| Polyurethane (UR) | 31.5 | 78.7 | 1.81 | - | - | - | - | 0.93 |

| Silicone (SR) | - | 19,685 | 118,110 | 17,717 | - | - | - | - |

Resistant to:

Moisture

Humidity

Sweat

Solvents

Thermal Properties

-

Melting point temperature up to 420°C

-

Allows for good heat dissipation

MEET ANY IP RATING

Parylene Thickness and Protection Levels

| Thickness (μm) | 0.1 to 5 | 5 to 12.5 | 12.5 to 25 | 12.5 to 50.8 |

| Relevant Standards | UT Type in IPC-CC-830C | UT Type in IPC-CC-830C | IPC-CC-830B | NASA-STD-8739.1B |

| Protection Level | IPX3 / IPX4 | IPX4 / IPX7 | IPX7 / IPX8 | IPX7 / IPX8 |

| Appropriate Products | Consumer Electronic & MEMS Devices | Consumer & Industrial Electronics | Aerospace, Automotive, Industrial, Medical Device, Telecom, & Other High-Reliability Markets | Aerospace, Defense, & Very Harsh Industrial |

HZO coatings pass IPC CC-830C testing at 50% film thickness of other conformal coatings

Chemical Resistance

Extremely resistant to solvents and reagents, including those listed below:

| Acids, Bases, Corrosives |

| Hydrochloric acid, 10% |

| Sulfuric acid, 10% |

| Nitric acid, 10% |

| Hydrofluoric acid, 10% |

| Sodium hydroxide solution, 10% |

| Ammonium hydroxide solution, 10% |

| Hydrogen peroxide in water (H2O2) |

| Organic Solvents |

| n-Octane |

| Toluene |

| Chlorobenzene |

| Pyridine |

| 2-Propanol (IPA) |

| Acetone |

Barrier Protection

Protect electronic components from:

-

Humidity

-

Dirt

-

Saltwater

-

Dust

-

Antifreeze

-

Cleaning products

-

Oil

-

Bodily fluids such as perspiration

-

Condensation

Optical Properties

-

Transparent, thin coating

-

Excellent transmission

-

Low optical absorption

ELECTRICAL PROPERTIES

HZO Parylene Electrical Properties

| Thickness (μm) | HZO Guardian Plus (Parylene C) | ASTM Method |

| Dielectric strength (V) @ 25.4 μm (1 mil) | 5,500 | D149 |

| Dielectric strength (V/μm) @ 25.4 μm (1 mil) | 220 | D149 |

| Dielectric constant (60 Hz) | 3.13 | D150 |

| Dielectric constant (1 kHz) | 3.01 | D150 |

| Dielectric constant (1 MHz) | 2.92 | D150 |

| Dissipation factor (60 Hz) | 0.022 | D150 |

| Dissipation factor (1 kHz) | 0.017 | D150 |

| Dissipation factor (1 MHz) | 0.013 | D150 |

| Volume resistivity (23 °C, 50% RH, Ω cm) | 6.0x1016 | D257 |

| Surface resistivity (23 °C, 50% RH, Ω) | 1.0x1015 | D257 |

Electrical Properties

-

Insulation

-

High dielectric strength

-

Good high-frequency properties with low dielectric constant

-

High bulk and surface resistance

Applications

University Research Projects

Outdoor Signage

Unmanned Aerial Vehicles

Electronics Manufacturing

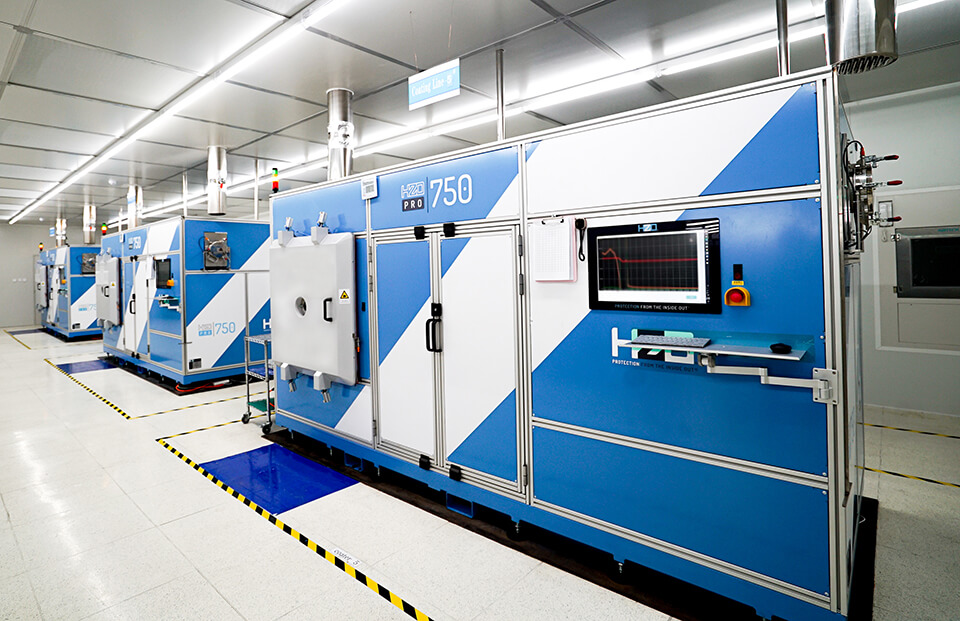

About Our Solution

In-house Designed Equipment

-

Optimized coating chambers decrease turnaround time

-

Throughput can be two times faster than the industry standard

Expertise

-

Dedicated engineers on your project from beginning to end

-

Market experience, rework and removal proficiency

Flexibility and Convenience

-

Scale to mass-production quickly with our proprietary equipment

-

Factory-in-factory or coating-as-a-service

Cost-efficiency and Cost Savings

-

Exceptional quality, zero product returns due to coating issues since our inception

-

IP (intellectual portfolio) backed masking automation reduces labor and costs

Additional Resources

Market Page

Learn More About the Benefits of Protective Consumer Electronics Coatings

Market Page

Learn About the Benefits of Protective Automotive Coatings

Market Page

Learn About the Benefits of Protective Industrial Coatings

Market Page

Learn About the Benefits of Protective Medical Device Coatings

Checklist